Aluminum Deep Drawing

Aluminum Deep Drawing - Web deep drawing press is a metal forming process where a flat sheet of metal, known as a blank, is molded into a specific shape by applying pressure. Web dry deep drawing of aluminum and the influence of sheet metal roughness. Deep drawing involves pulling a sheet of aluminum, or “blank”, into a die using a mechanical punch. Press speed (ram speed) draw radii; Web the deep drawing process is utilized for the manufacturing of sheet metal components in the automobile and aerospace industries. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. Web in short, aluminum deep drawing is the seamless deformation of an aluminum sheet into a hollow product that remains open on one side, such as a drinking cup. Volume 968, 15 december 2023, 171992. Aluminum deep drawing can be done in any possible shape, from cylindrical to square. Web deep drawing, a cornerstone of modern manufacturing, is a metal forming process that’s used to shape flat sheets of metal into seamless, hollow components.

Aluminum unfortunately often gets a. However, due to the oxidation and adhesion tendency of aluminium alloys, the tribological situations of aluminium alloy deep drawing (aadd) system is more complicated than those of traditional deep drawing of steel sheets. This column was prepared by the staff of the engineering research center for net shape manufacturing (erc/ nsm), the ohio state university, professor taylan altan, director. Enhanced deep drawing formability and deformation mechanism of aluminum alloy at cryogenic temperature. Web step 1—calculate blank sizes. Web the resulting parts and products are both strong and lightweight. Web dry deep drawing of aluminum and the influence of sheet metal roughness. An ideal product designed for an aluminum stretch draw. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. Dry metal shaping and forming.

Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat. Dry metal shaping and forming. The following article provides an overview of the aluminum deep drawing process. This column was prepared by the staff of the engineering research center for net shape manufacturing (erc/ nsm), the ohio state university, professor taylan altan, director. Aluminum unfortunately often gets a. The metal thickness, the metal type, and the blank size. Aluminum deep drawing can be done in any possible shape, from cylindrical to square. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. Web deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die with a punch.

Deep Drawing Aluminum Sheet Circle 1050 1060 Aluminum Plate ASTM B209

Web deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die with a punch. The present study briefs about the current developments in the deep drawing process at the elevated temperature. This column was prepared by the staff of the.

Aluminum Deep Drawing How Does It Work? The crafts person blog

Enhanced deep drawing formability and deformation mechanism of aluminum alloy at cryogenic temperature. Key elements in deep drawing. Aluminum unfortunately often gets a. In deep drawing, if the die clearance is too large, the component forms a cone instead of a cylinder. Journal of alloys and compounds.

Deep drawing of sheet metal

It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat. Web in short, aluminum deep drawing is the seamless deformation of an aluminum sheet into a hollow product that remains open.

Deep Drawn Aluminum Stampings from Charles Richter

Web deep drawing, a cornerstone of modern manufacturing, is a metal forming process that’s used to shape flat sheets of metal into seamless, hollow components. The present study briefs about the current developments in the deep drawing process at the elevated temperature. Web an investigation of the deep drawing behavior of automotive aluminum alloys at very low temperatures. Web the.

Custom Sheet Metal Stamping Process Copper Aluminum Deep Drawing Part

This column was prepared by the staff of the engineering research center for net shape manufacturing (erc/ nsm), the ohio state university, professor taylan altan, director. Web dry deep drawing of aluminum and the influence of sheet metal roughness. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. However, due to.

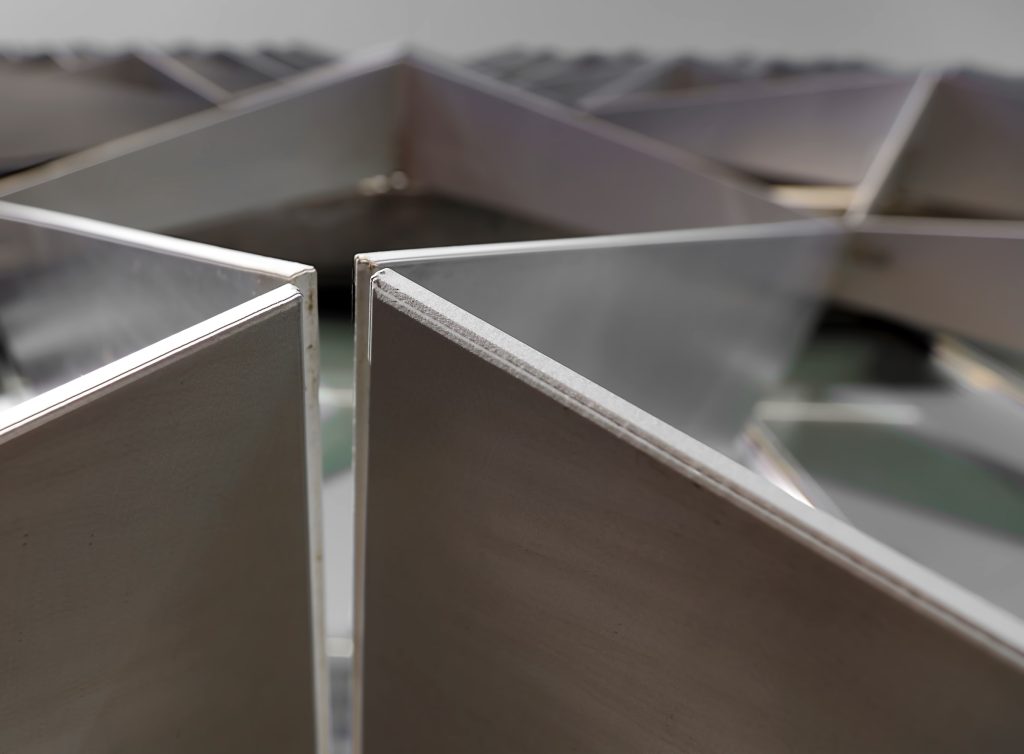

23 Years′ Stainless Steel Deep Drawing, Deep Draw Aluminum, Deep

The following article provides an overview of the aluminum deep drawing process. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. This action forms the metal into a seamless, hollow shape that can have a depth greater than its diameter, hence the term ‘deep’ drawing. Aluminum unfortunately.

Aluminum Deep Drawing Parts Metal Stamping

Web in short, aluminum deep drawing is the seamless deformation of an aluminum sheet into a hollow product that remains open on one side, such as a drinking cup. Enhanced deep drawing formability and deformation mechanism of aluminum alloy at cryogenic temperature. Web the resulting parts and products are both strong and lightweight. Press speed (ram speed) draw radii; This.

Aluminum Deep Draw YouTube

The metal thickness, the metal type, and the blank size. Web an investigation of the deep drawing behavior of automotive aluminum alloys at very low temperatures. Web deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die with a punch..

AMPCO® 25 Benefits of aluminum bronze for deep drawing

Web in short, aluminum deep drawing is the seamless deformation of an aluminum sheet into a hollow product that remains open on one side, such as a drinking cup. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. This action forms the metal into a seamless, hollow shape that can have.

Customized Deep Draw Metal Stamping , Good die material for aluminum

An ideal product designed for an aluminum stretch draw. This process stretches the aluminum into a shape that mirrors the die, which can range from simple forms like cups to complex components. In deep drawing, if the die clearance is too large, the component forms a cone instead of a cylinder. Web appropriate materials include aluminum alloys, brass, copper and.

To Calculate The Blank Size Needed For Drawing The Round Cup, Calculate The Surface Area Into A Flat.

Web in short, aluminum deep drawing is the seamless deformation of an aluminum sheet into a hollow product that remains open on one side, such as a drinking cup. Deep drawing involves pulling a sheet of aluminum, or “blank”, into a die using a mechanical punch. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. Web the deep drawing process is utilized for the manufacturing of sheet metal components in the automobile and aerospace industries.

An Ideal Product Designed For An Aluminum Stretch Draw.

This process stretches the aluminum into a shape that mirrors the die, which can range from simple forms like cups to complex components. Web deep drawing, a cornerstone of modern manufacturing, is a metal forming process that’s used to shape flat sheets of metal into seamless, hollow components. The following article provides an overview of the aluminum deep drawing process. Aluminum unfortunately often gets a.

This Action Forms The Metal Into A Seamless, Hollow Shape That Can Have A Depth Greater Than Its Diameter, Hence The Term ‘Deep’ Drawing.

Web deep drawing aluminum—not as hard as it looks. Web an investigation of the deep drawing behavior of automotive aluminum alloys at very low temperatures. Aluminum deep drawing can be done in any possible shape, from cylindrical to square. Dry metal shaping and forming.

The Process Involves Placing The Blank Onto A Die, Followed By The Application Of Force Through A Punch, Pushing The Material Into The Die.

You have full access to this open access article. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. Key elements in deep drawing. Felix flegler, peter groche, tim abraham & günter.

.jpg?width=700&name=304 deep drawing die 2 (1).jpg)