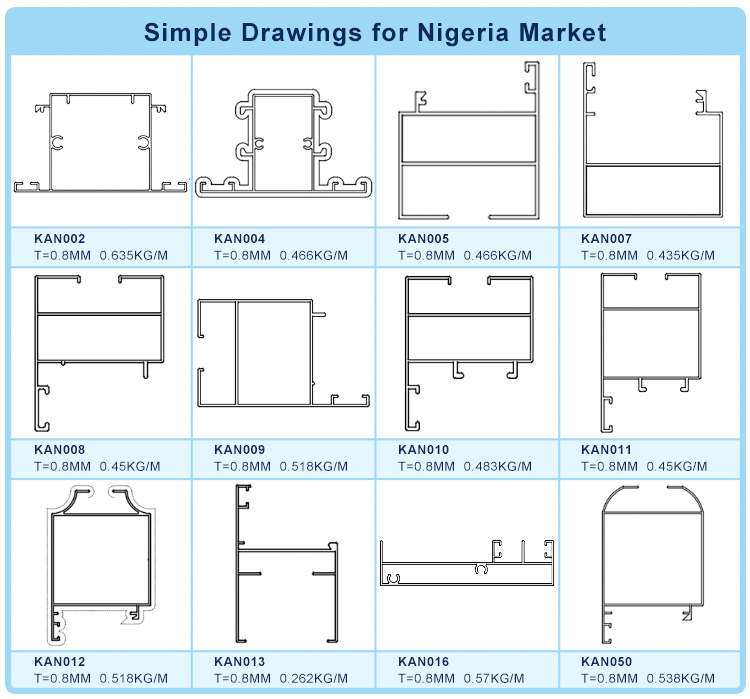

Aluminum Drawing

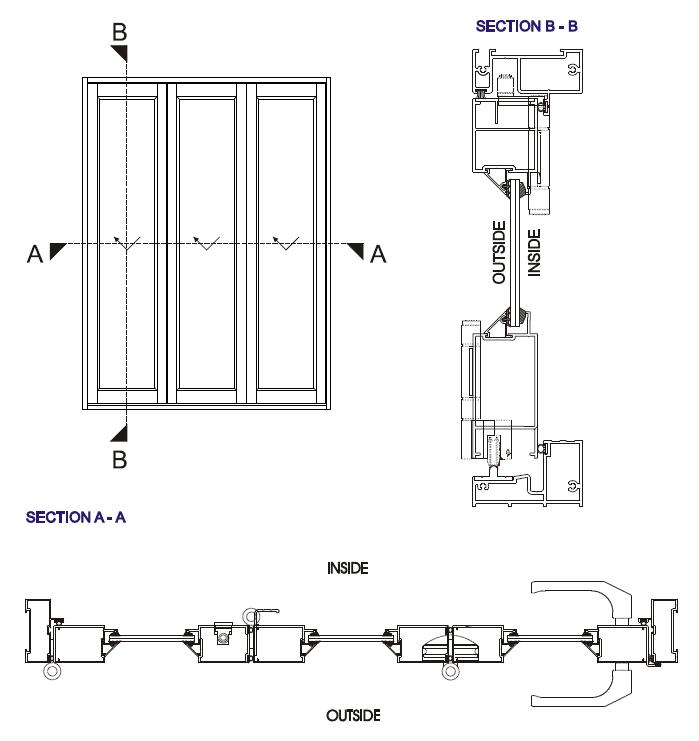

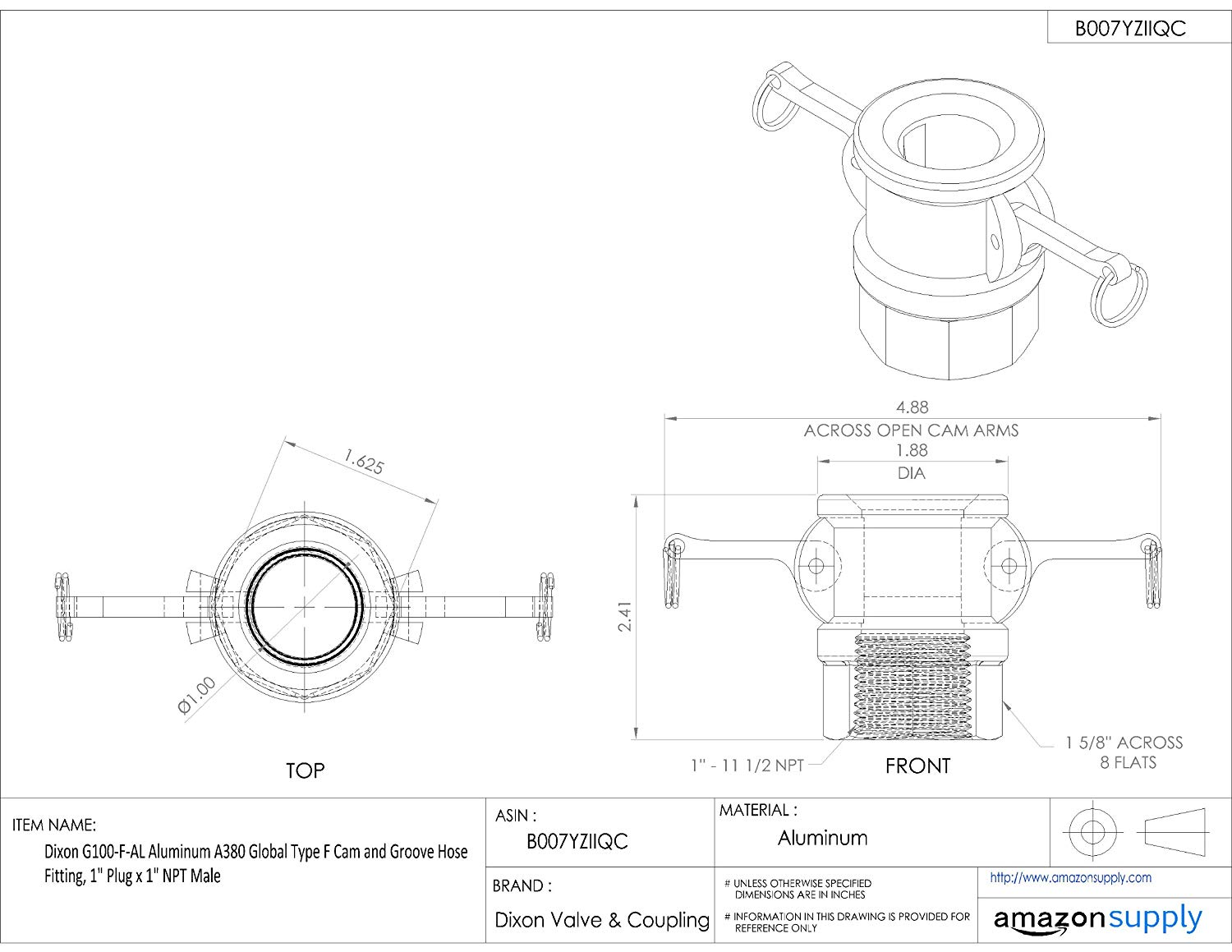

Aluminum Drawing - The metal thickness, the metal type, and the blank size. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. Different finishing processes may be specified depending on the use or application of the final product. Drawn tube is extruded tube which is further refined and brought to its final dimensions by being drawn through a die or series of dies. Web when it comes to aluminum shaping, there are two popular methods: Aluminum unfortunately often gets a bad rap. But that’s pretty much where the similarities end. If you need more information please reach out to us at jpurdy@mcelroymetal.com. Deep drawing involves pulling a sheet of aluminum, or “blank”, into a die using a mechanical punch. Web the drawings should primarily focus on delivering precise dimensions.

Web deep drawing is the process of forming a metal part from sheet stock, or a metal blank. Vc66 (mechanical) (op) 15 nov 07 11:39. To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat. Web neat oils for aluminum rod drawing can be in the viscosity range of kinematic viscosity (kv40c) 100 to 500 centistokes by the method astm d445, the actual viscosity can be dependent on the lubricant supplier and formulation. An ideal product designed for an aluminum stretch draw. Select the filter below to find applicable cad or pdf drawings. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. Lower viscosity oils are typically used for intermediate and fine wire sizes where the drawing oil is of a. Web deep drawing—also known as deep draw or deep drawn stamping—is a forming process used to create metal parts and products with heights equal to or greater than their widths. Web deep drawing uses extremely high forces to push a sheet or blank of a relatively soft alloy into a female draw cavity.

The metal thickness, the metal type, and the blank size. Web alumacomp is widely used for mounting fine art, photographs, linen and canvas to create an incredibly stable painting panel, or to use on its own as a reliable, archival painting support. Lower viscosity oils are typically used for intermediate and fine wire sizes where the drawing oil is of a. Web penn aluminum is a premier producer of drawn aluminum tube. Several stages are used in the process and appropriate lubrication is required. Web deep drawing uses extremely high forces to push a sheet or blank of a relatively soft alloy into a female draw cavity. Design table for stock sizes. If you need more information please reach out to us at jpurdy@mcelroymetal.com. Web by art hedrick. This may be a very simple question, but i couldn't find anything on it.

Aluminium Draw YouTube

Deep drawing is a valued fabrication method as it produces a seamless product. Design table for stock sizes. The metal thickness, the metal type, and the blank size. Web alumacomp is widely used for mounting fine art, photographs, linen and canvas to create an incredibly stable painting panel, or to use on its own as a reliable, archival painting support..

Atom model aluminium Stock Vector Images Alamy

For those manufacturing operations that revolve around the deep drawing of steel, the sheer mention of aluminum brings out a. We are here to help! Web penn aluminum is a premier producer of drawn aluminum tube. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. This process stretches the aluminum into a shape that.

Aluminium Drawings at Explore collection of

Drawn tube is extruded tube which is further refined and brought to its final dimensions by being drawn through a die or series of dies. Web the resulting parts and products are both strong and lightweight. If you need more information please reach out to us at jpurdy@mcelroymetal.com. Vc66 (mechanical) (op) 15 nov 07 11:39. Web alumacomp is widely used.

How to draw a metal ingot aluminium aluminum

Bright, matte, colored, brushed, other Vc66 (mechanical) (op) 15 nov 07 11:39. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. At asd we are committed to service, time, quality and responsibility in all our work. Web deep drawing is the process of forming a metal part from sheet stock, or a metal blank.

Aluminium Al (Element 13) of Periodic Table Elements FlashCards

Web the drawings should primarily focus on delivering precise dimensions. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. When comparing the two, there are a few key differences. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes..

18+ Aluminum Atome

Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. Both processes involve using a die or mold, and follow identical production guidelines: The metal thickness, the metal type, and the blank size. Web deep drawing uses extremely high forces to push a sheet or blank of a relatively soft alloy into.

Aluminium Drawings at Explore collection of

Web step 1—calculate blank sizes. Web by art hedrick. There are a number of factors to consider when specifying anodic finishes. Aluminum unfortunately often gets a bad rap. Read on to learn about the aluminum extrusion and drawing processes, as well as tips for how to choose which one is right for your project.

Aluminum Drawing at GetDrawings Free download

There are a number of factors to consider when specifying anodic finishes. Web step 1—calculate blank sizes. Great for plein air painting. Web aluminum material callout on drawing. Web deep drawing—also known as deep draw or deep drawn stamping—is a forming process used to create metal parts and products with heights equal to or greater than their widths.

Aluminium Drawings at Explore collection of

Aluminum is shaped into a billet and cut to a specific length. Some of the factors to be considered are: The following article provides an overview of the aluminum deep drawing process. Aluminum unfortunately often gets a bad rap. Read on to learn about the aluminum extrusion and drawing processes, as well as tips for how to choose which one.

Aluminum ClipArt ETC

It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. This may be a very simple question, but i couldn't find anything on it. This process stretches the aluminum into a shape that mirrors the die, which can range from simple forms like cups to complex components. Lower viscosity.

Web The Resulting Parts And Products Are Both Strong And Lightweight.

Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. When comparing the two, there are a few key differences. We are here to help! Web aluminum material callout on drawing.

It Discusses Why You Should Use Aluminum For Deep Drawing Operations And How The Material Is Formed During Deep Drawing Operations.

Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. If you need more information please reach out to us at jpurdy@mcelroymetal.com. Web alumacomp is widely used for mounting fine art, photographs, linen and canvas to create an incredibly stable painting panel, or to use on its own as a reliable, archival painting support. Drawn tube is extruded tube which is further refined and brought to its final dimensions by being drawn through a die or series of dies.

An Ideal Product Designed For An Aluminum Stretch Draw.

Great for plein air painting. Web deep drawing uses extremely high forces to push a sheet or blank of a relatively soft alloy into a female draw cavity. The drawing process provides exceptional dimensional control, with the ability to hold extremely tight tolerances, as well as a superior finish. I am checking a drawing of a simple bracket made out of aluminum 6061.

Design Table For Stock Sizes.

Both processes involve using a die or mold, and follow identical production guidelines: Web two of the most commonly used processes for shaping aluminum include the extrusion process and the drawing process. Lower viscosity oils are typically used for intermediate and fine wire sizes where the drawing oil is of a. Web penn aluminum is a premier producer of drawn aluminum tube.