Aws Pqr Form

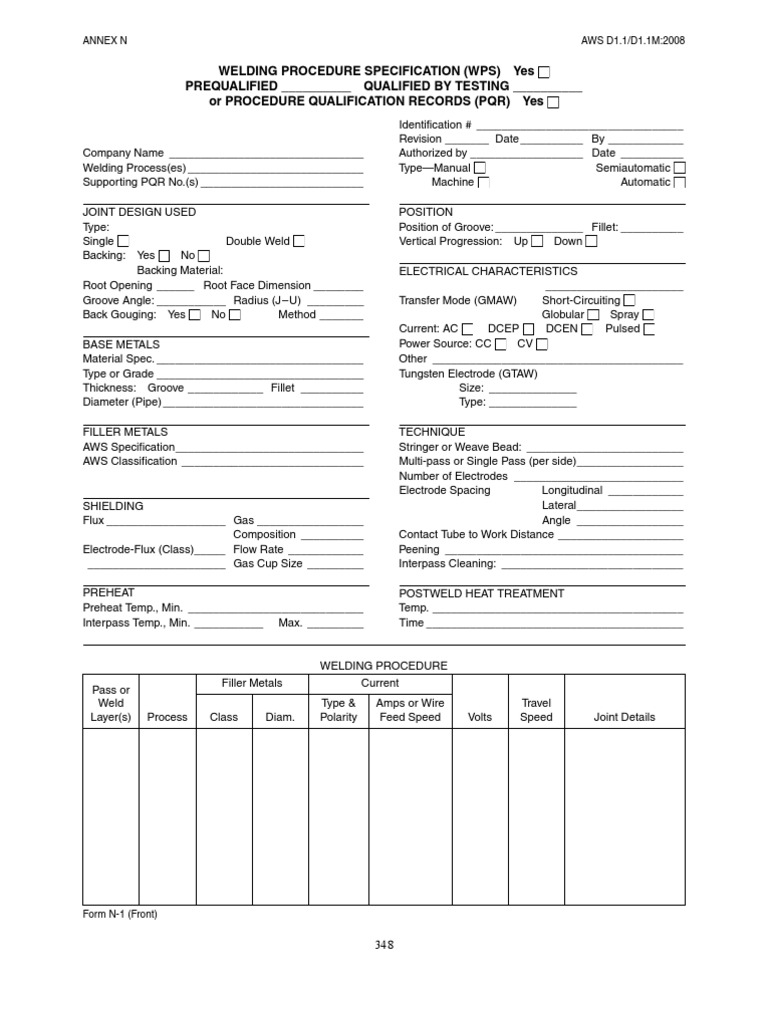

Aws Pqr Form - An example of a completed pqr form is provided for guidance in. Supporting pqr no.(s)_____ mechanized automatic joint design used. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form continuation of procedure qualification record (pqr) no. Type of bend result remarks visual inspection: Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. (year) date tested_____ qualifier signature _____. Web procedure qualification record (pqr) test results we, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and. Web procedure qualification record (pqr) test results we, the undersigned, certify that the statements in this record are correct and that the test welds were. The request from the user. Optional photo id product form specification (type or grade) number group.

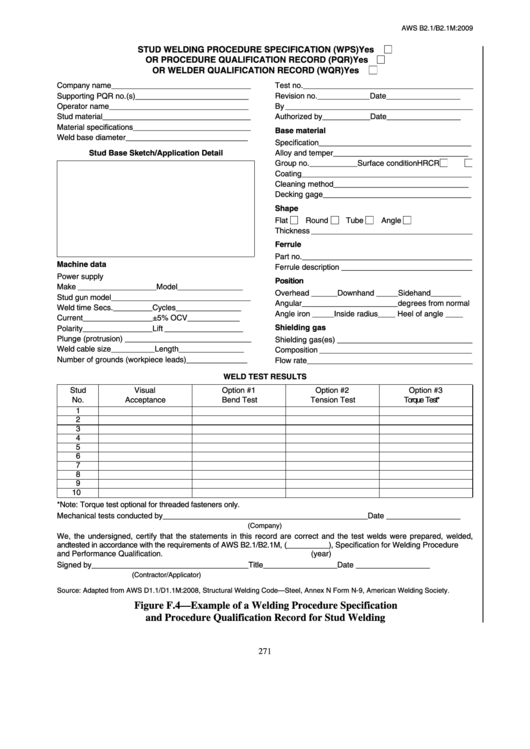

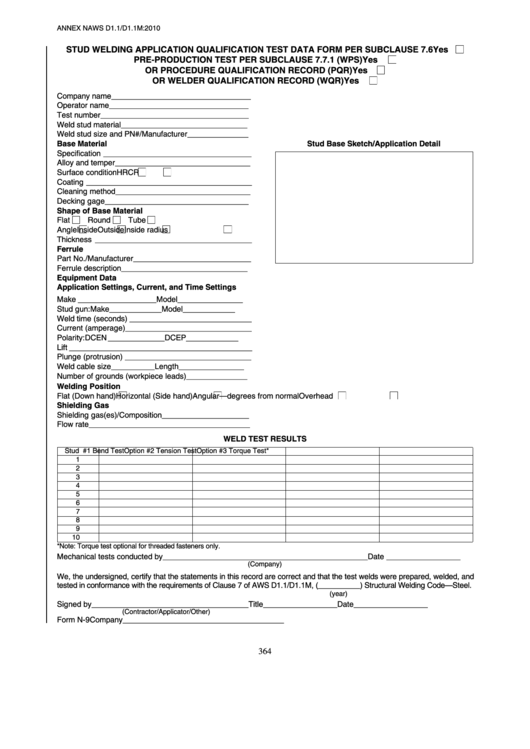

(year) date tested_____ qualifier signature _____. Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Supporting pqr no.(s)_____ mechanized automatic joint design used. An example of a completed pqr form is provided for guidance in. Optional photo id product form specification (type or grade) number group. Web aws b2.1/b2.1m:2009 270 electrical characteristics and welding parameters (see 4.13.8) other variables (see 4.14.9) current type/polarity_____ cup or nozzle size _____. Web for the pqr, the actual joint details and the values of essential variables used in the testing should be recorded. Web procedure qualification record (pqr) groove weld test specimen no. Width thickness area ultimate tensile load, lb ultimate unit stress, psi character of. Web procedure qualification record (pqr) test results we, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and.

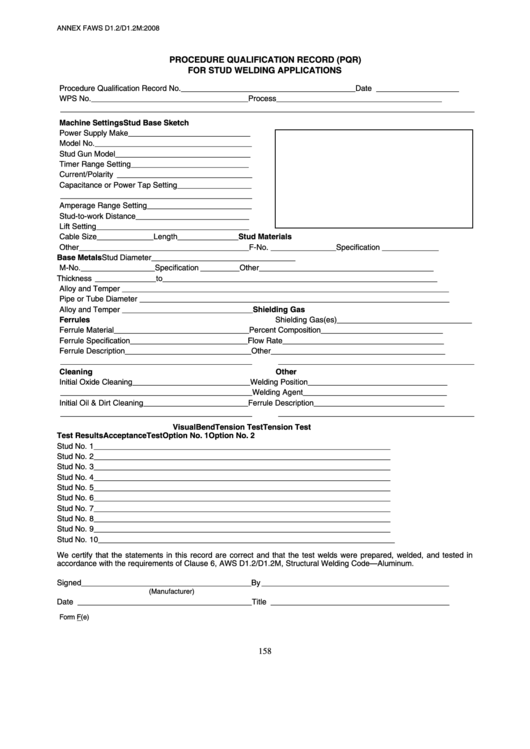

Web procedure qualification record (pqr) groove weld test specimen no. Web for the pqr, the actual joint details and the values of essential variables used in the testing should be recorded. Web with the requirements of aws b2.1/b2.1m, (_____), specification for welding procedur e and performance qualification. An example of a completed pqr form is provided for guidance in. Web aws b2.1/b2.1m:2009 270 electrical characteristics and welding parameters (see 4.13.8) other variables (see 4.14.9) current type/polarity_____ cup or nozzle size _____. Width thickness area ultimate tensile load, lb ultimate unit stress, psi character of. Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form continuation of procedure qualification record (pqr) no. Optional photo id product form specification (type or grade) number group. (year) date tested_____ qualifier signature _____.

F(d)Stud Welding WPS Form

Type of bend result remarks visual inspection: Supporting pqr no.(s)_____ mechanized automatic joint design used. Web procedure qualification record (pqr) test results we, the undersigned, certify that the statements in this record are correct and that the test welds were. Web procedure qualification record (pqr) groove weld test specimen no. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form.

WPSPQRWPQPEIPL

Supporting pqr no.(s)_____ mechanized automatic joint design used. Web with the requirements of aws b2.1/b2.1m, (_____), specification for welding procedur e and performance qualification. Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Web procedure qualification record (pqr) test results we, the undersigned, certify that the statements in this record are correct and that the test welds were..

Aws Wpspqr Form

Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form continuation of procedure qualification record (pqr) no. An example of a completed pqr form is provided for guidance in. Web aws b2.1/b2.1m:2009 270 electrical characteristics and welding parameters (see 4.13.8) other variables (see 4.14.9) current type/polarity_____ cup or nozzle.

Aws 209 Pqr Form [PDF Document]

Web product form welded to test date record no. Web with the requirements of aws b2.1/b2.1m, (_____), specification for welding procedur e and performance qualification. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form continuation of procedure qualification record (pqr) no. Web procedure qualification record (pqr) groove weld test specimen no. Web annex n aws d1.1/d1.1m:2010 354 welding procedure.

WPS AWS Template

Optional photo id product form specification (type or grade) number group. Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Web product form welded to test date record no. (year) date tested_____ qualifier signature _____. Web procedure qualification record (pqr) groove weld test specimen no.

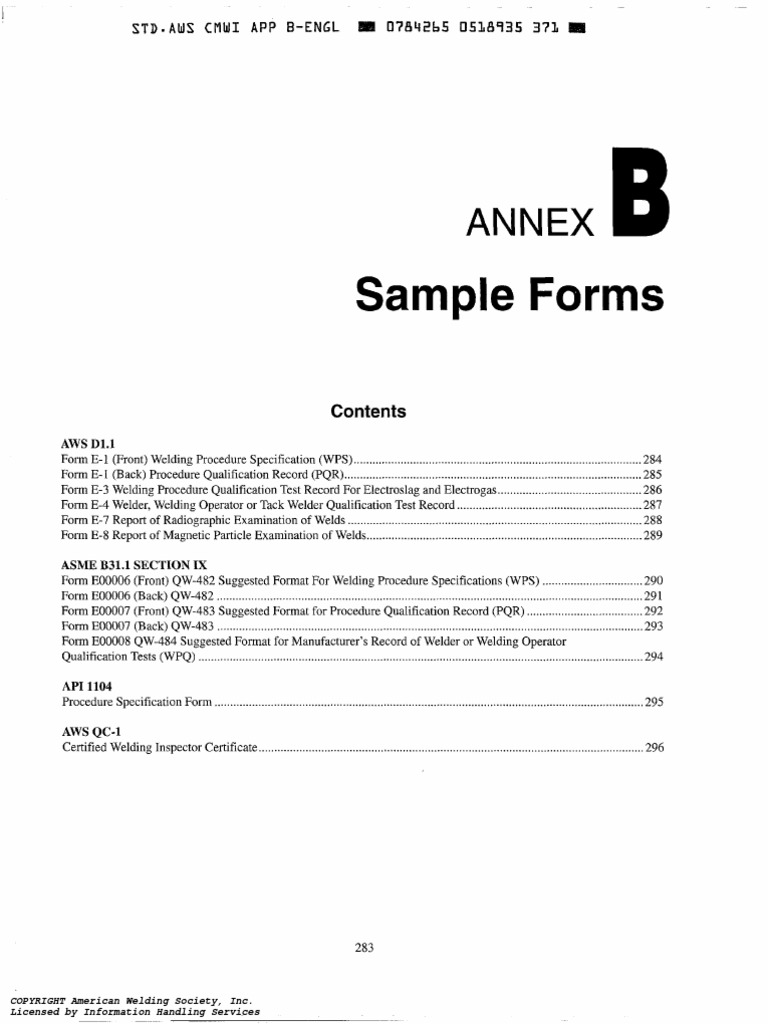

Sample Forms AWS, ASME and API

Web procedure qualification record (pqr) test results we, the undersigned, certify that the statements in this record are correct and that the test welds were. Width thickness area ultimate tensile load, lb ultimate unit stress, psi character of. Optional photo id product form specification (type or grade) number group. Supporting pqr no.(s)_____ mechanized automatic joint design used. Web aws d1.4/d1.4m:2011.

Fillable Stud Welding Procedure Specification (Wps) Form Or Procedure

Width thickness area ultimate tensile load, lb ultimate unit stress, psi character of. Type of bend result remarks visual inspection: Supporting pqr no.(s)_____ mechanized automatic joint design used. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form continuation of procedure qualification record (pqr) no. The request from the user.

Fillable Form Aws D1.1 Stud Welding Procedure Specification (Wps

Web product form welded to test date record no. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form continuation of procedure qualification record (pqr) no. Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Web with the requirements of aws b2.1/b2.1m, (_____), specification for welding procedur e and performance qualification. Web procedure qualification record (pqr) test results.

AWS N9 Stud Welding Procedure Specification (WPS) Form

Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Web with the requirements of aws b2.1/b2.1m, (_____), specification for welding procedur e and performance qualification. Optional photo id product form specification (type or grade) number group. Type of bend result remarks visual inspection: Web product form welded to test date record no.

Fillable Form F(E) Procedure Qualification Record (Pqr) For Stud

The request from the user. An example of a completed pqr form is provided for guidance in. Web procedure qualification record (pqr) groove weld test specimen no. Width thickness area ultimate tensile load, lb ultimate unit stress, psi character of. Supporting pqr no.(s)_____ mechanized automatic joint design used.

Web Procedure Qualification Record (Pqr) Test Results We, The Undersigned, Certify That The Statements In This Record Are Correct And That The Test Welds Were Prepared, Welded, And.

Web for the pqr, the actual joint details and the values of essential variables used in the testing should be recorded. Web aws b2.1/b2.1m:2009 270 electrical characteristics and welding parameters (see 4.13.8) other variables (see 4.14.9) current type/polarity_____ cup or nozzle size _____. Optional photo id product form specification (type or grade) number group. An example of a completed pqr form is provided for guidance in.

(Year) Date Tested_____ Qualifier Signature _____.

Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes. Type of bend result remarks visual inspection: The request from the user. Width thickness area ultimate tensile load, lb ultimate unit stress, psi character of.

Supporting Pqr No.(S)_____ Mechanized Automatic Joint Design Used.

Web procedure qualification record (pqr) groove weld test specimen no. Web with the requirements of aws b2.1/b2.1m, (_____), specification for welding procedur e and performance qualification. Web aws d1.4/d1.4m:2011 55 sample procedure qualification record (pqr) form continuation of procedure qualification record (pqr) no. Web product form welded to test date record no.

![Aws 209 Pqr Form [PDF Document]](https://cdn.vdocuments.net/img/1200x630/reader024/reader/2021012118/552b44ef4a79593a588b4621/r-1.jpg?t=1630219684)