Calendering Of Fabric

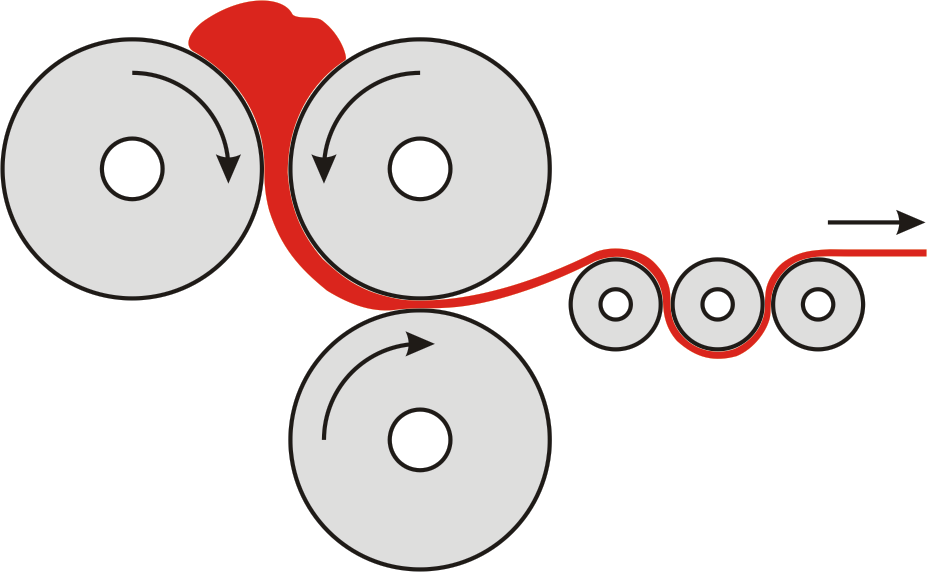

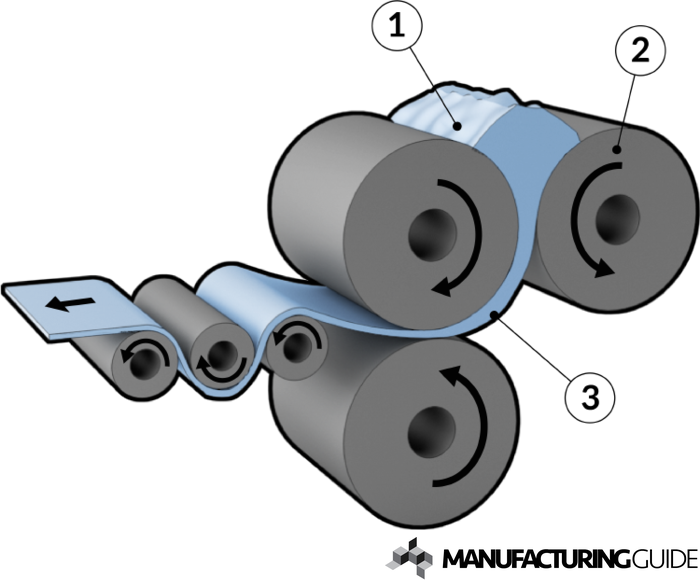

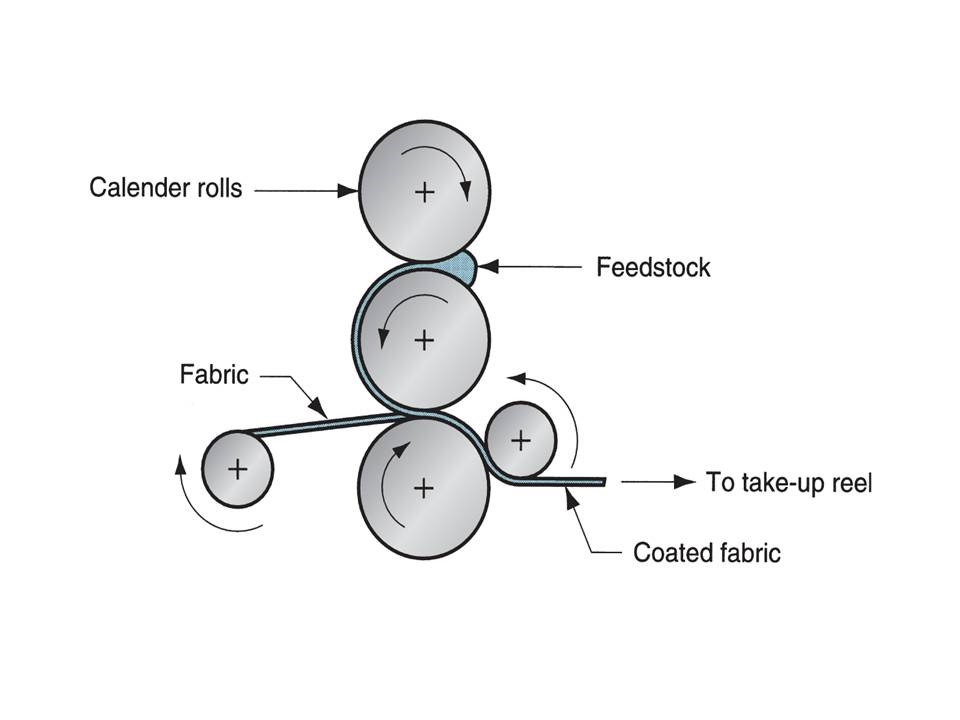

Calendering Of Fabric - Calendering involves passing fabric through horizontal rollers that apply heat and. Web calendaring is a mechanical fabric finishing process. The entire process is performed under controlled. An improved fabric lustre results after the calendaring process. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Web the calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. Web calendering | objective of fabric calender finishing process#fabric #textiletv #finishing calendaring is a mechanical finishing process used on cloth where f. Web understanding the best fabric for calendering is crucial for achieving the desired finish, whether you're working with cotton, polyester, or blends. The rotation speed and pressure of. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated.

A smooth, glossy, or embossed surface is produced by passing cloth through rollers while it is heated and compressed. Web calendering | objective of fabric calender finishing process#fabric #textiletv #finishing calendaring is a mechanical finishing process used on cloth where f. Web textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering, embossing, and friction calendering. The entire process is performed under controlled. Web calendering is a textile finishing process that involves passing fabric between two or more heavy rollers to smooth and polish its surface. However, most film and sheet are prepared by extrusion techniques (cha. Web calendering is a finishing technique used in the textile industry to modify the surface texture and enhance the appearance of fabrics. Stylish effects and highly functional properties thanks to innovative finishing. Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or rollers. The rollers are typically made of.

Web calendering is a textile finishing process that involves passing fabric between two or more heavy rollers to smooth and polish its surface. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Definition and mechanism of calendering. Web the calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. An improved fabric lustre results after the calendaring process. However, most film and sheet are prepared by extrusion techniques (cha. Web 4 key benefits of calendering for fabrics 1. The rollers are typically made of. The rotation speed and pressure of. These different techniques can provide different:

Fabric Calendering Process Nina Teresa

The process involves passing the fabric. Web calendaring is a mechanical fabric finishing process. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Definition and mechanism of calendering. Calendering adds luster and texture to various.

Fabric Calendering Process Nina Teresa

The rotation speed and pressure of. Calendering adds luster and texture to various. The process involves passing the fabric. Web calendering | objective of fabric calender finishing process#fabric #textiletv #finishing calendaring is a mechanical finishing process used on cloth where f. The rollers are typically made of.

Calendering:Woven Fabric Finishing Process textilewebinfo

The rotation speed and pressure of. Web the calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. An improved fabric lustre results after the calendaring process. The process involves passing the fabric. However, most film and sheet are prepared by extrusion techniques (cha.

Fabric Calendering Process Nina Teresa

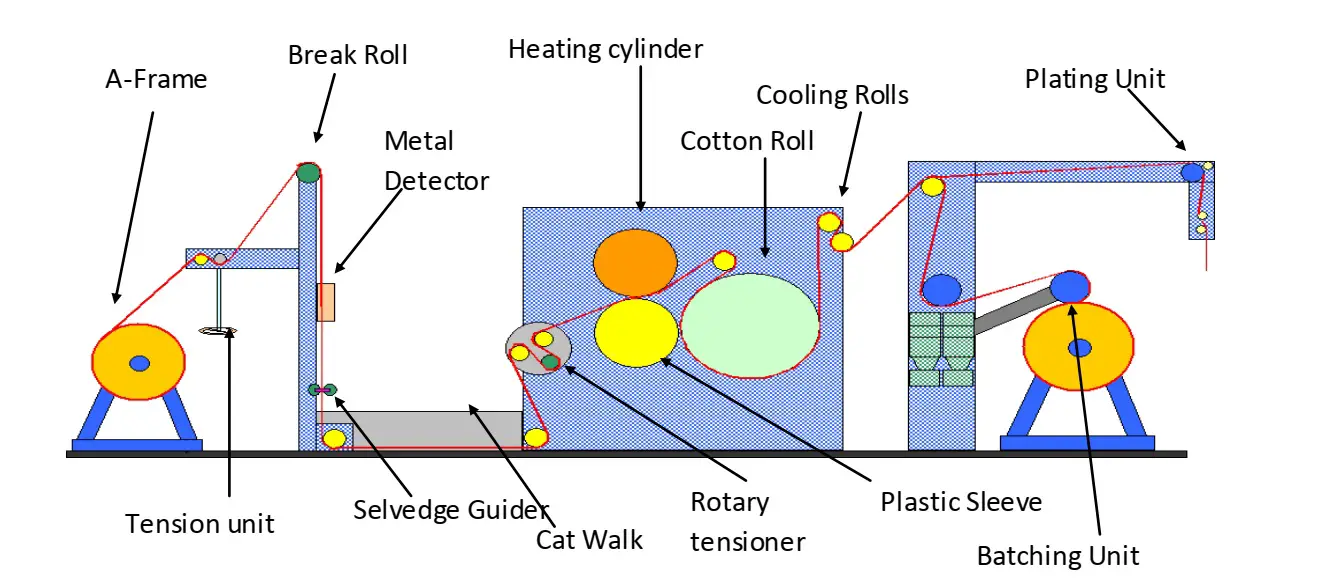

Calendering adds luster and texture to various. Calender rolls are also used to form some. Web calendaring is a mechanical fabric finishing process. Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or rollers. Mechanical finishing process in which fabric is passed between two rollers (one metal and one cotton fabric).

Calendering Find suppliers, processes & material

Calendering adds luster and texture to various. Calendering involves passing fabric through horizontal rollers that apply heat and. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. The process involves passing the fabric. Web calendering is a finishing technique used in.

10 Facts About Calendering in Textile! Textile Property

Calendering involves passing fabric through horizontal rollers that apply heat and. Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or rollers. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. These.

Calendering Of Fabric Lilas Marcelia

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. The rollers are typically made of. However, most film and sheet are prepared by extrusion techniques (cha. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to.

State Several Reasons For A Fabric To Be Calendered Tova Atlanta

The entire process is performed under controlled. Web calendaring is a mechanical fabric finishing process. Mechanical finishing process in which fabric is passed between two rollers (one metal and one cotton fabric) under heavy pressure to create a variety of flattened. The process involves passing the fabric. Calender rolls are also used to form some.

Calendering Factors Effecting Calendering Calendering Machine

Mechanical finishing process in which fabric is passed between two rollers (one metal and one cotton fabric) under heavy pressure to create a variety of flattened. Calendering adds luster and texture to various. However, most film and sheet are prepared by extrusion techniques (cha. The rotation speed and pressure of. Web calendering is a textile finishing process that involves passing.

State Several Reasons For A Fabric To Be Calendered Tova Atlanta

Web calendering is a finishing technique used in the textile industry to modify the surface texture and enhance the appearance of fabrics. A smooth, glossy, or embossed surface is produced by passing cloth through rollers while it is heated and compressed. Calendering adds luster and texture to various. Mechanical finishing process in which fabric is passed between two rollers (one.

Stylish Effects And Highly Functional Properties Thanks To Innovative Finishing.

Web understanding the best fabric for calendering is crucial for achieving the desired finish, whether you're working with cotton, polyester, or blends. A smooth, glossy, or embossed surface is produced by passing cloth through rollers while it is heated and compressed. Calendering involves passing fabric through horizontal rollers that apply heat and. Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics.

The Rotation Speed And Pressure Of.

Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting,. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. The entire process is performed under controlled. Web calendering is a finishing technique used in the textile industry to modify the surface texture and enhance the appearance of fabrics.

However, Most Film And Sheet Are Prepared By Extrusion Techniques (Cha.

Mechanical finishing process in which fabric is passed between two rollers (one metal and one cotton fabric) under heavy pressure to create a variety of flattened. Calendering adds luster and texture to various. Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or rollers. Definition and mechanism of calendering.

Web Calendering Is A Textile Finishing Process That Involves Passing Fabric Between Two Or More Heavy Rollers To Smooth And Polish Its Surface.

These different techniques can provide different: Web textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering, embossing, and friction calendering. Web calendering | objective of fabric calender finishing process#fabric #textiletv #finishing calendaring is a mechanical finishing process used on cloth where f. Web 4 key benefits of calendering for fabrics 1.