Drawing In Textile

Drawing In Textile - Web the weaver’s beam is obtained from sectional warping or sizing. Web the drawing process in textiles: There are mainly three actions are involved in draw frame, which are drafting, doubling and drawing. Web textile designing is the art of creating patterns and textures for fabric through various mediums. With help of drawing you can trace your idea and sketch of your product on the paper first then you can also draw some roughs patterns. This article was most recently revised and updated by robert curley. It is a system which removes stable/weak and brittle properties of filaments. This process is called drafting and drafting operation increases the unevenness. Web how to draw silk and satin. Web the main objectives of the draw frame process are given below:

Half and full crosses, dots, squares and lines. It’s at the very core of fashion and is a huge part of interior design, too. One of the main tasks of draw frame is improving evenness over short, medium and especially long terms. This technique can be used to create intricate and detailed designs, and can also be used to create a rough sketch. Drawing, in yarn manufacture, process of attenuating the loose assemblage of fibres called sliver ( q.v.) by passing it through a series of rollers, thus straightening the individual fibres and making them more parallel. The process by which the yarn or fiber is elongated by passing it through a series of pair of rollers, each pair moving faster than the previous one is called drawing. Invented in the 1730s by lewis paul and john wyatt, the spinning machine operated by drawing cotton or wool through pairs of successively faster rollers. These pattern pieces became building blocks for constructing portraits of people. The filament fiber must be drawn to develop. It is a system which removes stable/weak and brittle properties of filaments.

• to improve the fibre arrangement in the sliver and to make the fibres parallel to the sliver length. The technique, which dates back centuries, involves the straightening, paralleling,. Web the drawing process in textiles: It was eventually superseded by r. The tasks of draw frame are equalizing, parallelizing, blending and dust removing. Web drawing is one of the most basic techniques for producing textile designs. With help of drawing you can trace your idea and sketch of your product on the paper first then you can also draw some roughs patterns. I set myself a task of creating 12 different patterns based on the same grid system. Web textile designing is the art of creating patterns and textures for fabric through various mediums. The process by which the yarn or fiber is elongated by passing it through a series of pair of rollers, each pair moving faster than the previous one is called drawing.

Fabric texture drawing Textile pattern design fashion, Textile

In this step by step tutorial, you will learn how to draw silk and…. Web there are three main steps of weaving preparatory process: Each pair of rollers spins faster than the previous one. Carded slivers are fed to the draw frame have degree on unevenness that cannot be tolerated in practice and slivers from the comber contain the “infamous”.

Textile Art by Julie Mortillaro Julie Dawn Designs

To get optimal value for strength in the yarn characteristics, the fibers must be arranged parallel in the fiber strand. Drawing, in yarn manufacture, process of attenuating the loose assemblage of fibres called sliver ( q.v.) by passing it through a series of rollers, thus straightening the individual fibres and making them more parallel. While it’s likely been around since.

Textile art, Pattern art, Embroidery art

The filament fiber must be drawn to develop. Whether you are a beginner or have some experience, youll explore a variety of techniques and strategies that you can use to refine and develop your ideas. The tasks of draw frame are equalizing, parallelizing, blending and dust removing. Involves creating a design by hand using pencil, ink, or paint on paper..

ARTS THREAD Textiles sketchbook, Textile art, A level textiles

The weaver’s beam is obtained from sectional warping or sizing. To get optimal value for strength in the yarn characteristics, the fibers must be arranged parallel in the fiber strand. • to improve the uniformity (linear density) of sliver up to optimum level. Web the main objectives of the draw frame process are given below: Web the weaver’s beam is.

Textile Design How To Draw Easy Textile Design YouTube

Web draw frame is the machine where the slivers are doubled or combined, blended & mixed, leveled and attenuated transiently through a series of pairs of rollers. Drawing, in yarn manufacture, process of attenuating the loose assemblage of fibres called sliver ( q.v.) by passing it through a series of rollers, thus straightening the individual fibres and making them more.

Textile Adviser DRAWING IN PROCESS, A WEAVING PROCESS

Carded slivers are fed to the draw frame have degree on unevenness that cannot be tolerated in practice and slivers from the comber contain the “infamous” piecing. It’s at the very core of fashion and is a huge part of interior design, too. It is a system which removes stable/weak and brittle properties of filaments. You'll work with a range.

How to Draw Textile Design Textile Design Textile Design Drawing

Working on paper, youll learn some core drawing and painting skills essential to achieve good results in textile design. While it’s likely been around since people. Invented in the 1730s by lewis paul and john wyatt, the spinning machine operated by drawing cotton or wool through pairs of successively faster rollers. You can choose to add extra water for a.

Floral Textile Design Patterns Drawing Course The Print School

Web tasks of draw frame. • to improve the uniformity (linear density) of sliver up to optimum level. Web the main objectives of the draw frame process are given below: The technique, which dates back centuries, involves the straightening, paralleling,. It was eventually superseded by r.

How To Draw Textile Design YouTube

This article was most recently revised and updated by robert curley. Web drawing frame, machine for drawing, twisting, and winding yarn. Tasks of the draw frame. Half and full crosses, dots, squares and lines. The process by which the yarn or fiber is elongated by passing it through a series of pair of rollers, each pair moving faster than the.

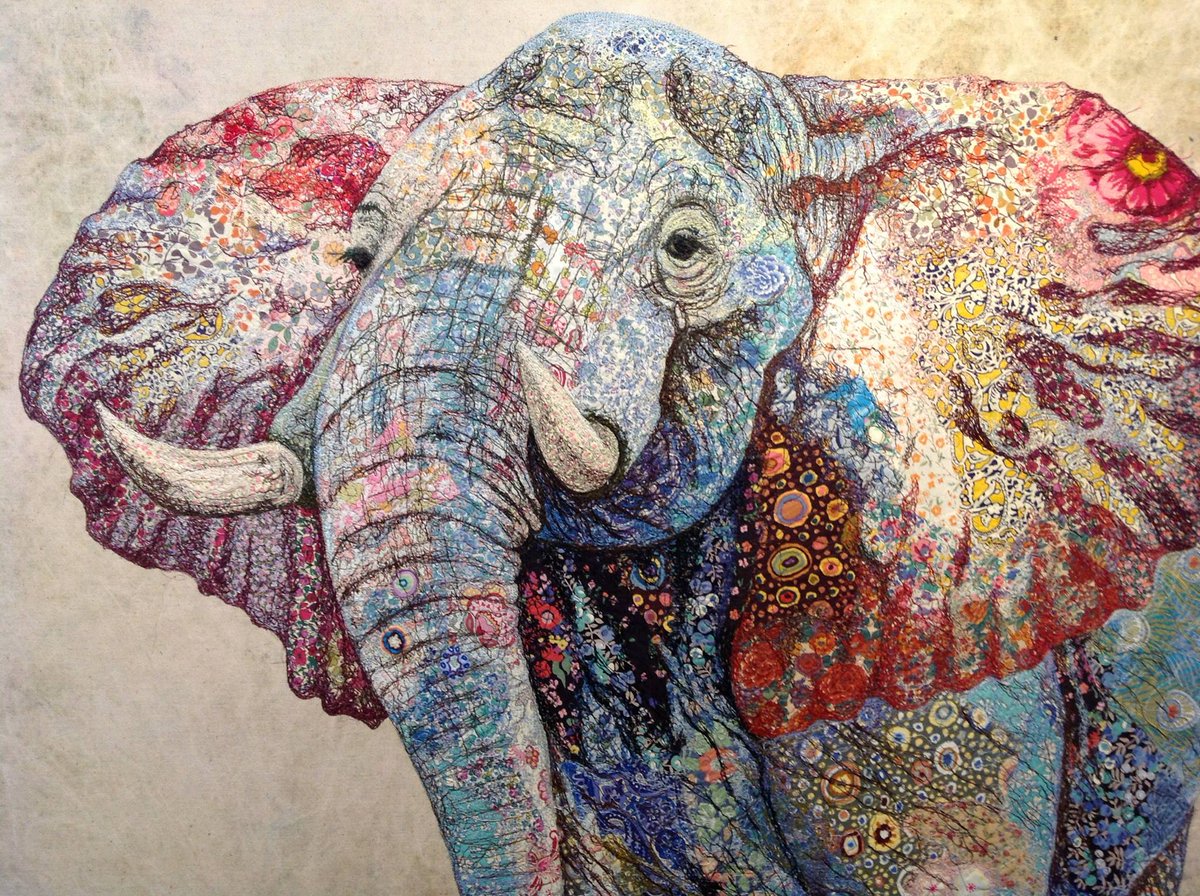

TOUCHING HEARTS Textile embroidery by British fine artist SOPHIE STANDING

Half and full crosses, dots, squares and lines. The key purpose of implementing draw frames to spinning procedure is to develop the yarn. The drawing process is a crucial stage in textile manufacturing, specifically in the production of yarns from natural fibers like cotton and wool. It was eventually superseded by r. There are mainly three actions are involved in.

The Main Objective Of The Draw Frame Is Equalizing.

These pattern pieces became building blocks for constructing portraits of people. Half and full crosses, dots, squares and lines. It’s at the very core of fashion and is a huge part of interior design, too. Carded slivers are fed to the draw frame have degree on unevenness that cannot be tolerated in practice and slivers from the comber contain the “infamous” piecing.

The Tasks Of Draw Frame Are Equalizing, Parallelizing, Blending And Dust Removing.

Web techniques of textile design: Invented in the 1730s by lewis paul and john wyatt, the spinning machine operated by drawing cotton or wool through pairs of successively faster rollers. This technique can be used to create intricate and detailed designs, and can also be used to create a rough sketch. Web tasks of draw frame.

In This Step By Step Tutorial, You Will Learn How To Draw Silk And….

Web the weaver’s beam is obtained from sectional warping or sizing. This article was most recently revised and updated by robert curley. It is a system which removes stable/weak and brittle properties of filaments. The function of draw frame is to provide doubling and drawing at the same time.

After Extrusion Of The Fiber, Its Chainlike Molecules Are In An Amorphous Or Disordered Arrangement.

Web in this process, the sliver is elongated, doubled, leveled when passing through pairs of rollers. Calculations play an important role during the drawing. Web in 2011 i started a stitch portrait project. Each pair of rollers spins faster than the previous one.