Drawing Manufacturing

Drawing Manufacturing - Requirements to the set of drawings: The aec industry tends to use. Deep drawing is a popular sheet metal forming method that is. Web design adaptations like minimizing material usage, reducing complexity, or optimizing for faster production times can help control costs across different. The first step in dfm automation is gathering all the known design factors present within your board. Drawing is a metalworking process which uses tensile forces. Whether you’re creating the very first. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical. The purpose of this guide is to give you. The purpose is to convey all the information necessary for manufacturing a product or a part.

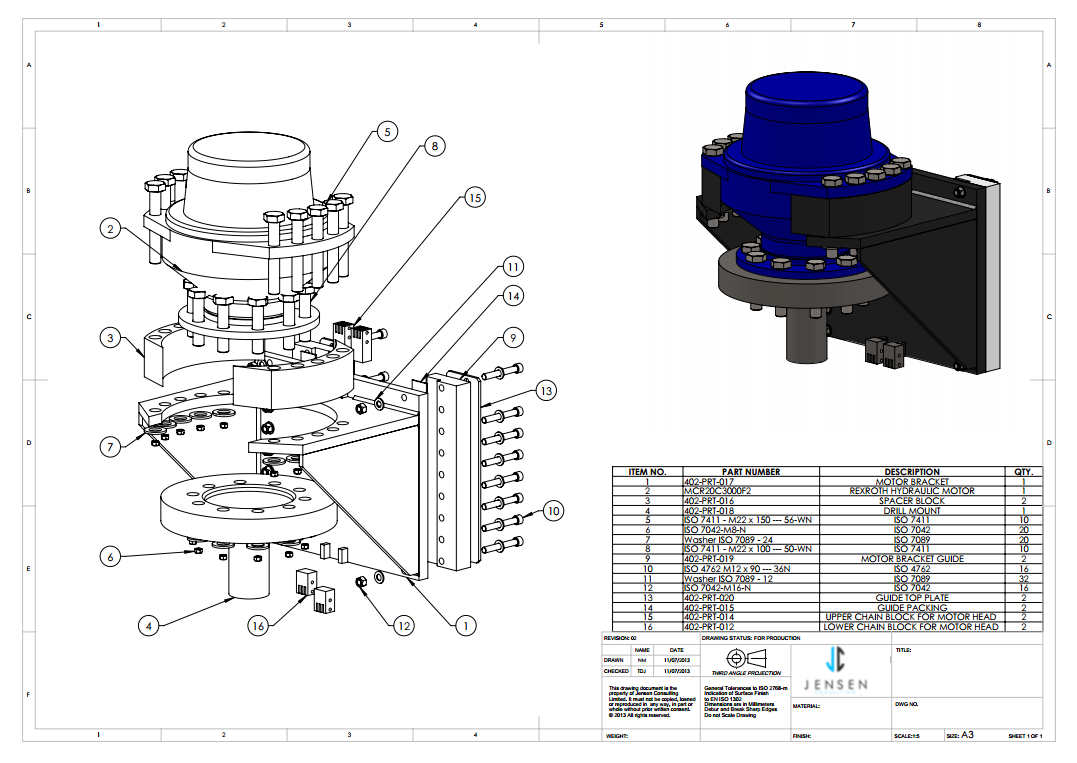

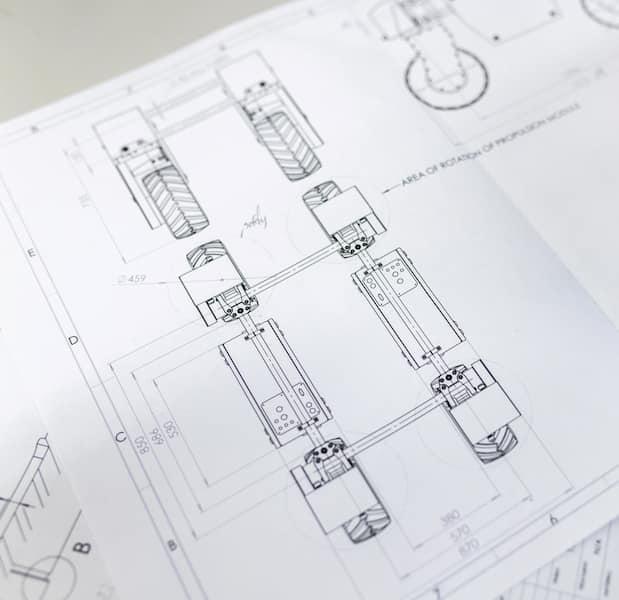

Web 2.materials, design and methods. This is especially true for the engineer. Web working drawings are the blueprints used for manufacturing products. Designcraft offers specialty services for professional companies engaged in new product development and rapid manufacturing. Web one of the best ways to communicate one’s ideas is through some form of picture or drawing. Web these drawings provide a detailed representation of how various components come together to form a complete assembly, guiding manufacturers, engineers, and. 9/16/2022 | 5 min read. Web an engineering drawing is a subcategory of technical drawings. The purpose of this guide is to give you. It enables companies to achieve components with exceptional repeatability and accuracy at a lower cost.

Drawing is a metalworking process which uses tensile forces. The aec industry tends to use. These manual processes can lead to inefficiencies, including. Web headly manufacturing is a leading contract manufacturer of precision drawn metal stamping to the automotive industry as well as others. The sharp tip of a micropipette contacts with a polymer solution droplet and. Web 2.materials, design and methods. Requirements to the set of drawings: The purpose of this guide is to give you. The overarching methodology of the present study includes: Web drawing is a manufacturing process for producing a wire, bar or tube by pulling on a material until it increases in length.

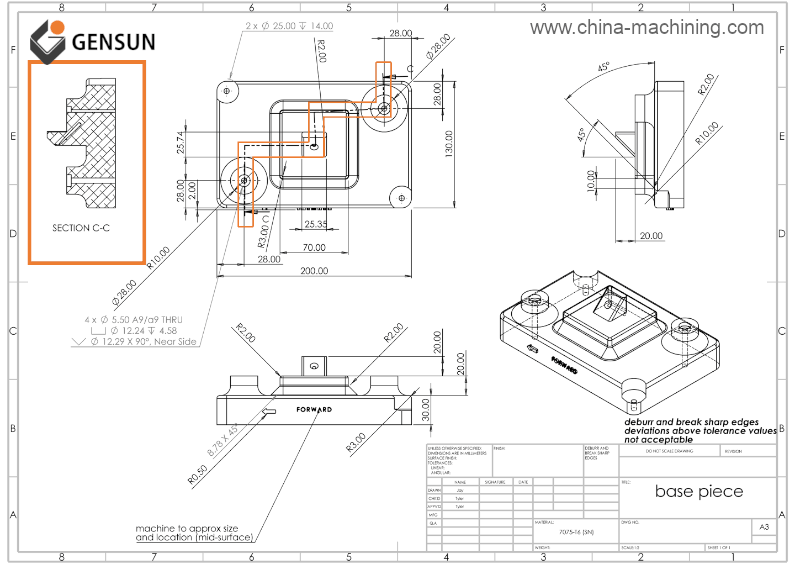

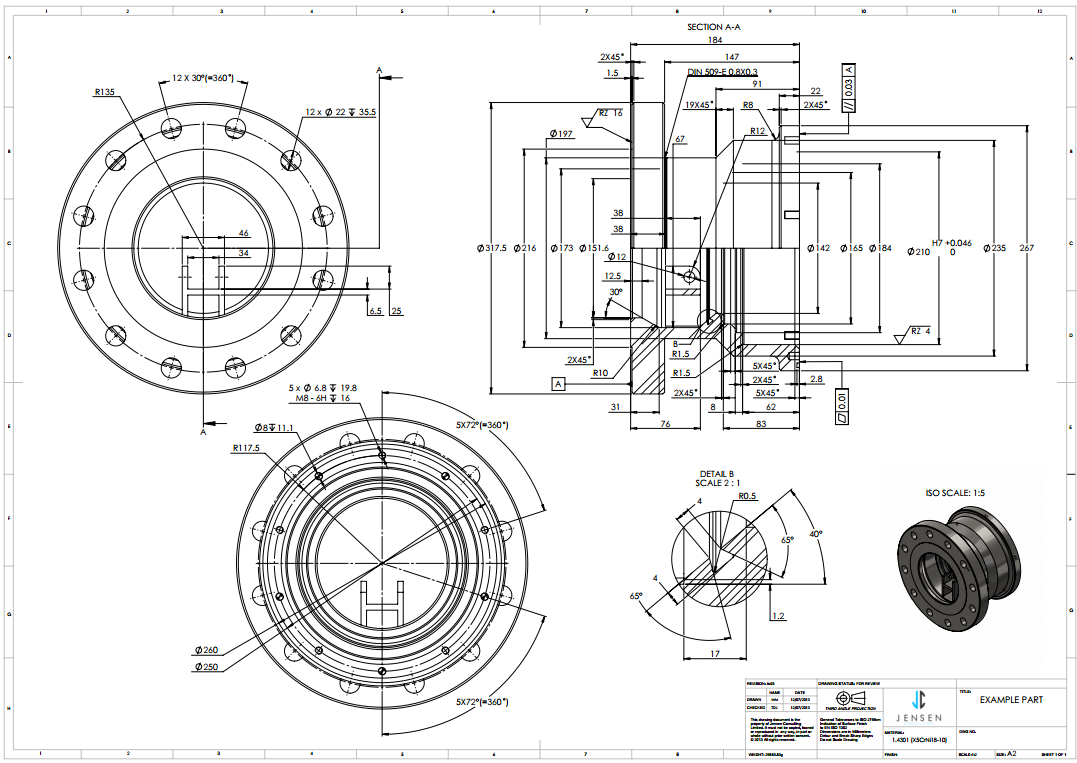

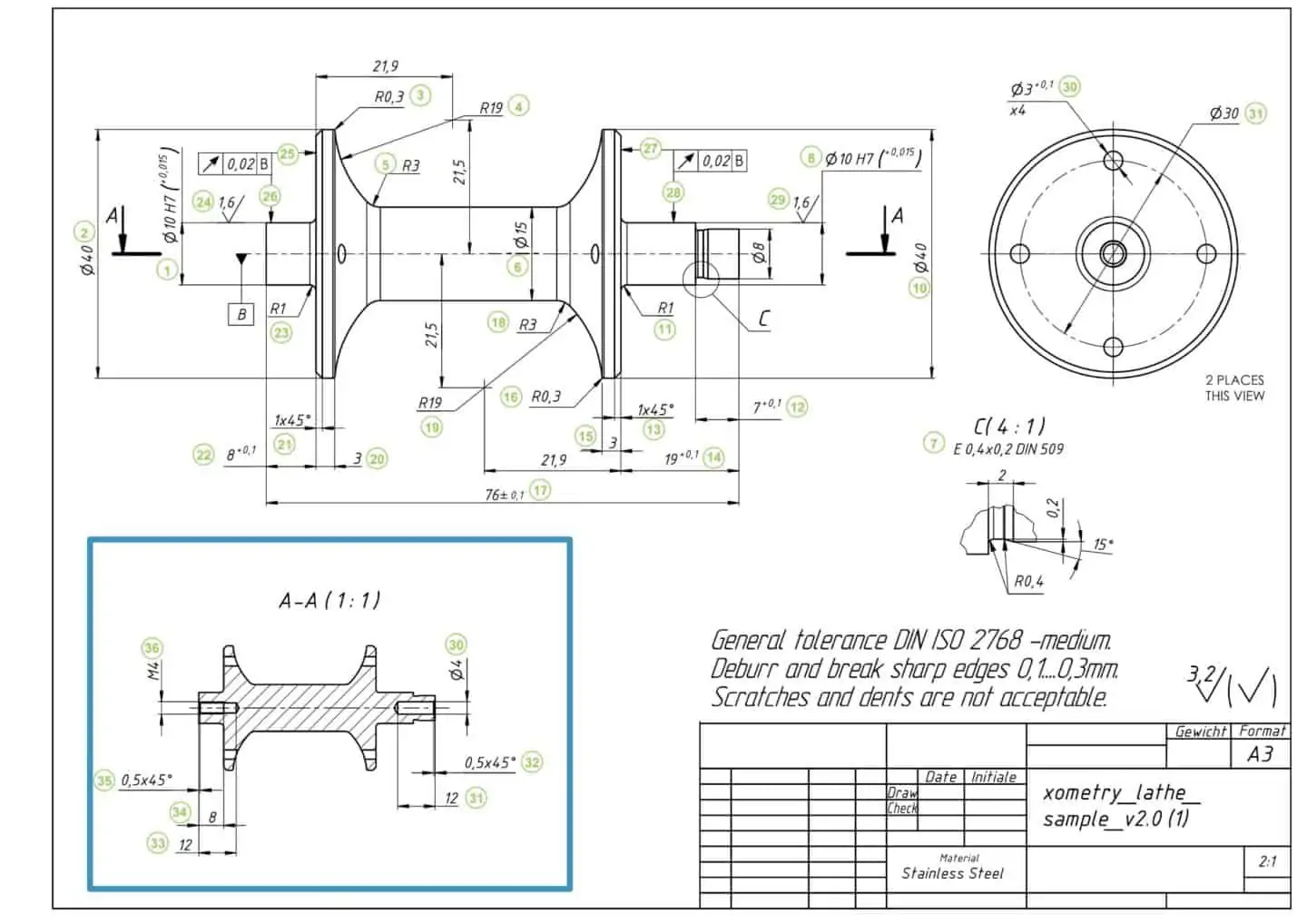

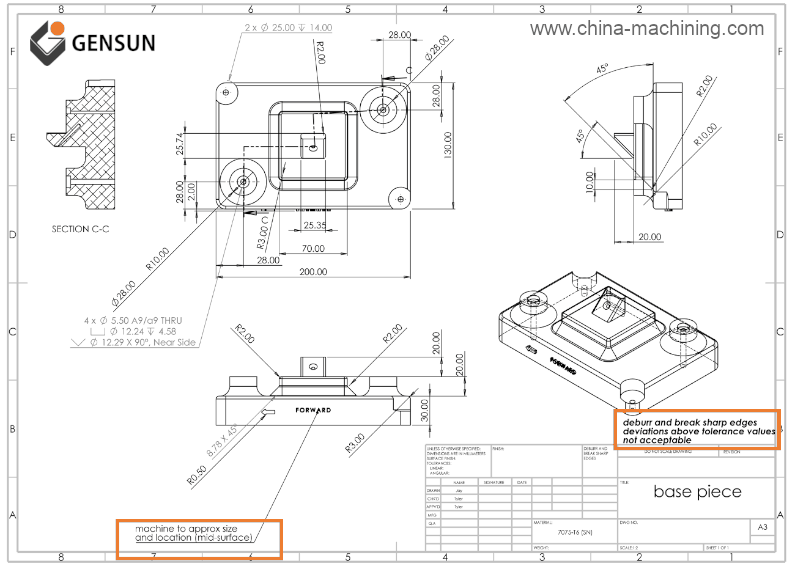

2D Technical Drawings CNC Machining Service

To completely describe the parts, both visually and dimensionally;. Deep drawing is a popular sheet metal forming method that is. Web drawing is a manufacturing process for producing a wire, bar or tube by pulling on a material until it increases in length. Web working drawings are the blueprints used for manufacturing products. Requirements to the set of drawings:

How to Draw a Factory Really Easy Drawing Tutorial

The overarching methodology of the present study includes: Web one of the best ways to communicate one’s ideas is through some form of picture or drawing. 9/16/2022 | 5 min read. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical. The purpose is to convey all the.

How to Create Great Technical Drawings in Manufacturing

Web inventory management often involves repetitive tasks such as stock counting, replenishment and tracking. The overarching methodology of the present study includes: Web technical drawings (and the process of drafting) are a means of conveying information between engineers and manufacturers. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of.

Manufacturing Drawing and Drafting Services Graphix Technologies

The sharp tip of a micropipette contacts with a polymer solution droplet and. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical. The purpose is to convey all the information necessary for manufacturing a product or a part. The overarching methodology of the present study includes: To.

Industrial Drawings at Explore collection of

Web working drawings are the blueprints used for manufacturing products. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical. These best practices apply to 2d. Web the mission of alanson manufacturing is to meet world class performance standards and excellence in our products by: Web an engineering.

How To Prepare A Perfect Technical Drawing Xometry Europe

Drawing is a metalworking process which uses tensile forces. Web drawing is a manufacturing process for producing a wire, bar or tube by pulling on a material until it increases in length. Deep drawing is a popular sheet metal forming method that is. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers.

How to Draw a Factory Really Easy Drawing Tutorial

These best practices apply to 2d. Web in the dynamic realm of custom processing and manufacturing, where accuracy, efficiency, and collaboration are paramount, engineering drawing serves as a. Designcraft offers specialty services for professional companies engaged in new product development and rapid manufacturing. Web one of the best ways to communicate one’s ideas is through some form of picture or.

How to Create Great Technical Drawings in Manufacturing

The first step in dfm automation is gathering all the known design factors present within your board. Web the mission of alanson manufacturing is to meet world class performance standards and excellence in our products by: Web an engineering drawing is a subcategory of technical drawings. Web drawing is a manufacturing process for producing a wire, bar or tube by.

Manufacturing Drawing at Explore collection of

Requirements to the set of drawings: 9/16/2022 | 5 min read. Drawing is a metalworking process which uses tensile forces. The sharp tip of a micropipette contacts with a polymer solution droplet and. Web 2.materials, design and methods.

MANUFACTURING DRAWING PRODUCTION DRAWING Drafting Australia

These manual processes can lead to inefficiencies, including. Web one of the best ways to communicate one’s ideas is through some form of picture or drawing. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical. Web in the dynamic realm of custom processing and manufacturing, where accuracy,.

Drawing Is A Metalworking Process Which Uses Tensile Forces.

Web drawing is a manufacturing process for producing a wire, bar or tube by pulling on a material until it increases in length. Web one of the best ways to communicate one’s ideas is through some form of picture or drawing. These best practices apply to 2d. Web working drawings are the blueprints used for manufacturing products.

Requirements To The Set Of Drawings:

This is especially true for the engineer. Web design adaptations like minimizing material usage, reducing complexity, or optimizing for faster production times can help control costs across different. Web 2.materials, design and methods. Web drawing process is based on micropipette or glass rod application to obtain a desired structure.

The Purpose Is To Convey All The Information Necessary For Manufacturing A Product Or A Part.

These manual processes can lead to inefficiencies, including. 9/16/2022 | 5 min read. To completely describe the parts, both visually and dimensionally;. Web inventory management often involves repetitive tasks such as stock counting, replenishment and tracking.

This Time In The Knowledge Series, We Will Discuss The Difference Between Manufacturing Drawing And Engineering Drawing.

Web an engineering drawing is a subcategory of technical drawings. A design factor is a. The overarching methodology of the present study includes: This is typically accompanied by a thinning out of.