How To Draw Value Stream Mapping

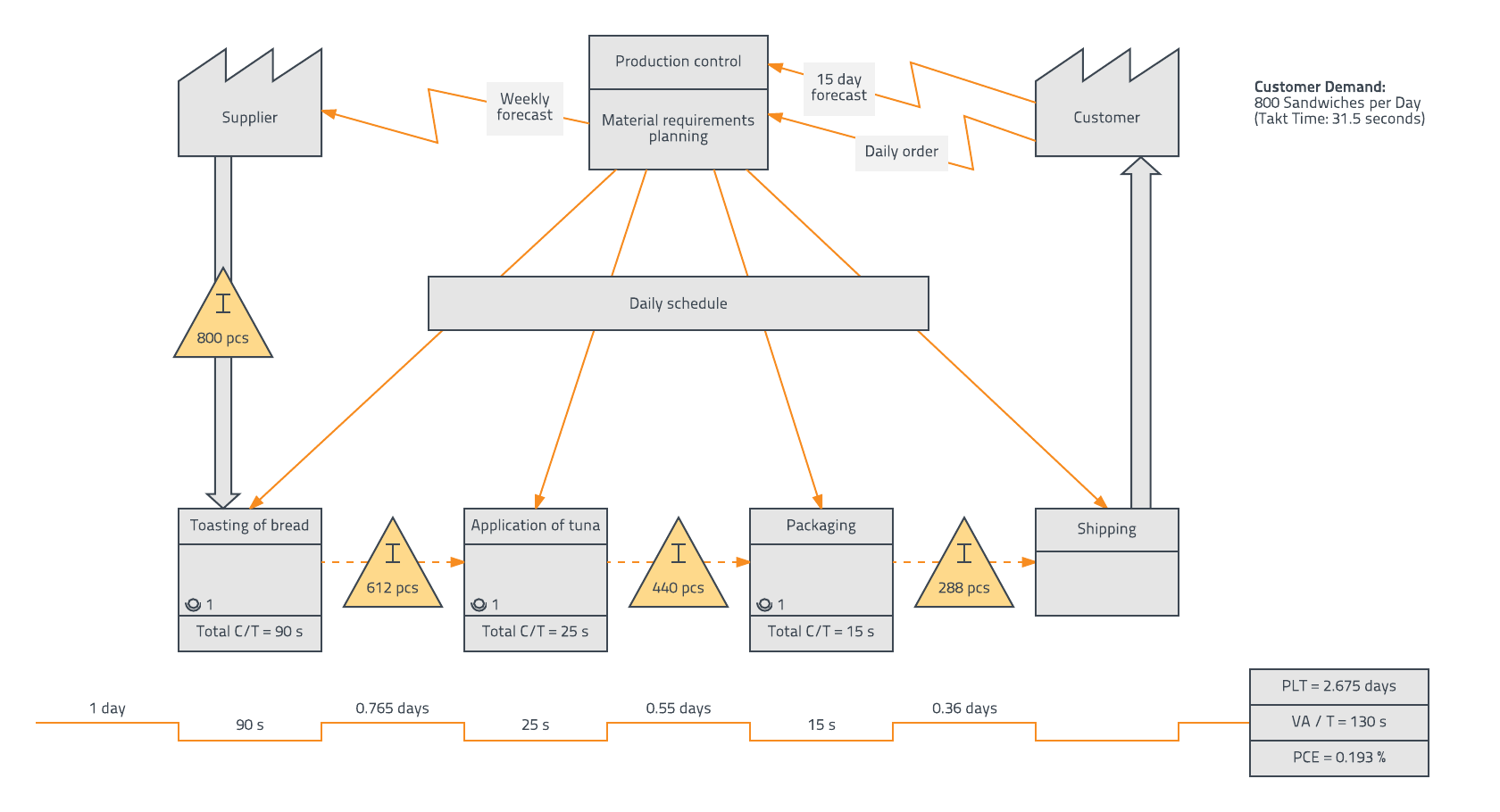

How To Draw Value Stream Mapping - Value stream mapping is a technique — developed from lean manufacturing — that organizations use to create a visual guide of all the components necessary to deliver a product or service, with the goal of analyzing and optimizing the entire process. Web there are 8 steps to developing a powerful value stream map: Value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. Web simply follow these steps. Define the basic value stream. Web first, draw a rough sketch of the entire value stream (of information and material flow) to help everyone involved understand the skeleton of the map. A revolutionary technique in lean business. Start from the most downstream processes (from the customer end) and move upstream as you draw the current state map. Draw the supplier (s) draw the customer (s) draw the processing steps. The best way to understand value stream maps is to look at some examples of value stream maps.

Start from the most downstream processes (from the customer end) and move upstream as you draw the current state map. Web value stream mapping (vsm) is a lean management method used to understand and analyse the current state process map and design a future state for the series of events that take a product or service from raw material and information into a complete product for the customer. It is better to create by hand and involve the entire team in its creation rather than have an expert take the information and return later with a finished map! For more complex value streams there would be need for higher levels of knowledge. Set project focus and scope. Value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. Draw the supplier (s) draw the customer (s) draw the processing steps. Draw a simple flow chart first. Web let’s talk about how to do a value stream map and start analyzing your process. Web lean / value stream mapping.

Web there are 8 steps to developing a powerful value stream map: Initially developed as part of the lean manufacturing methodology, vsm has since evolved and found application in a wide range of industries, including knowledge work sectors such as it, software. At the start, a whiteboard and markers might be enough to put together a decent value stream. It is clear that drawing value stream maps is a specialist skill. The process indicates a step in the flow of operations. A key part of lean methodology, vsm reviews the flow of process steps and information from origin to delivery to the customer. Web you can create a value stream map in just five steps using figjam’s value stream map template. 200k views 6 years ago value stream mapping tutorial. Web value stream mapping (vsm) is a lean management method used to understand and analyse the current state process map and design a future state for the series of events that take a product or service from raw material and information into a complete product for the customer. Web there are two steps to using value stream maps:

Value Stream Mapping Software Create a Value Stream Map Rapidly

Start from the most downstream processes (from the customer end) and move upstream as you draw the current state map. The most important aspect of a vsm is the visualization of the steps in a process. Web lean / value stream mapping. With smartdraw, you can create more than 70 types of diagrams, charts, and visuals. Create a current state.

How to Create a Value Stream Map Mapping your value stream VSM

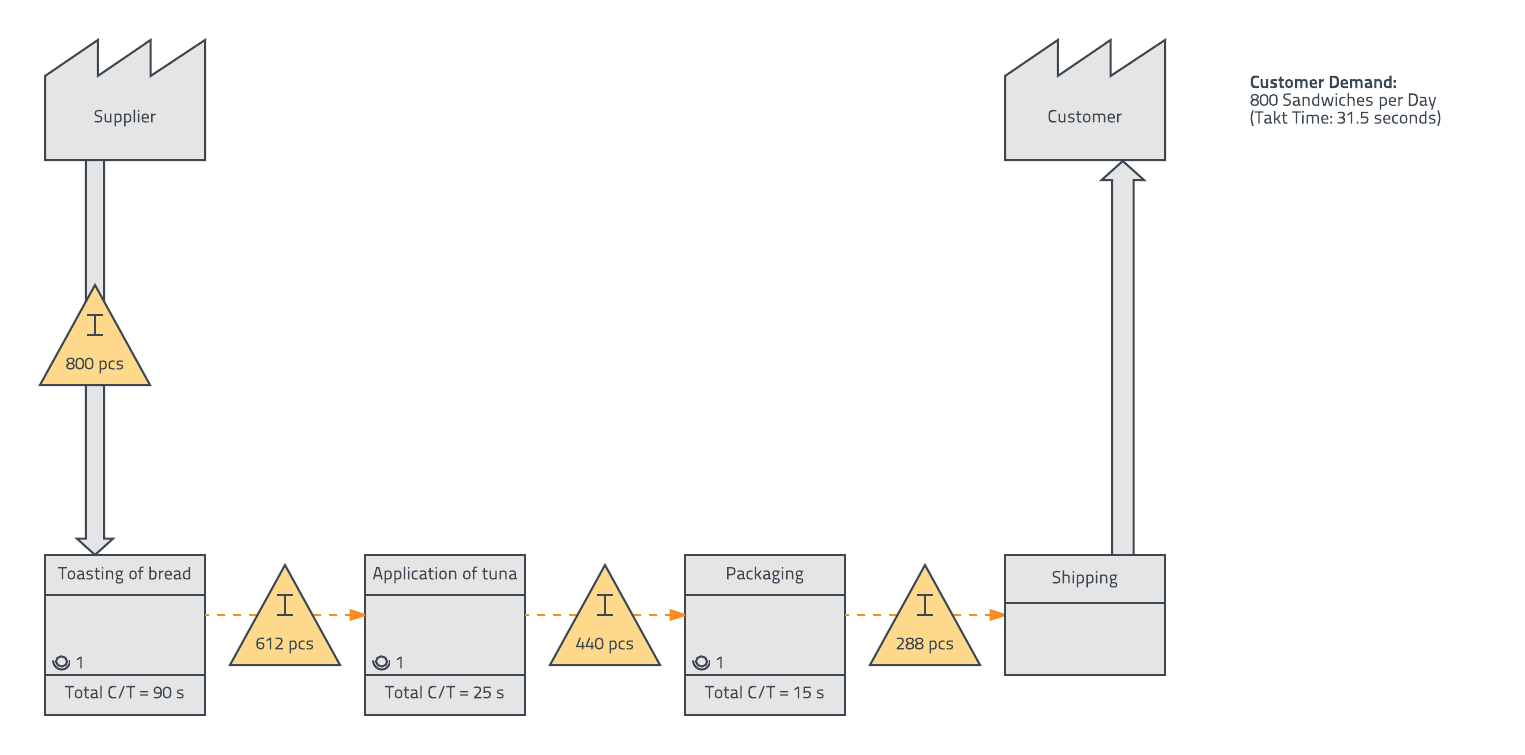

Vsm or value stream mapping, the first step to improving any process is to understand it. The best way to understand value stream maps is to look at some examples of value stream maps. 200k views 6 years ago value stream mapping tutorial. It helps visualize, analyze, and improve all the steps involved by identifying waste and reducing process cycle.

Create a Value Stream Map Value Stream Mapping Software

For some organizations, the basics might be enough. For more complex value streams there would be need for higher levels of knowledge. The best way to understand value stream maps is to look at some examples of value stream maps. If you’re using lucidchart to complete your diagram, make sure to use our value stream map template or add our.

How to Create a Value Stream Map Lucidchart Blog

It offers a detailed overview on everything. Web value stream mapping (vsm) is a lean management method used to understand and analyse the current state process map and design a future state for the series of events that take a product or service from raw material and information into a complete product for the customer. Download the pdf with the..

How to Create a Value Stream Map Lucidchart Blog

The process indicates a step in the flow of operations. It helps visualize, analyze, and improve all the steps involved by identifying waste and reducing process cycle times. For more complex value streams there would be need for higher levels of knowledge. For some organizations, the basics might be enough. Web you can create a value stream map in just.

The Ultimate Guide to Value Stream Mapping by Creately Thousand

Draw a simple flow chart first. Web there are 8 steps to developing a powerful value stream map: Web a value stream map is best created by hand using a pencil (you will need to make frequent corrections and changes) on a sheet of a3 paper. Start from the most downstream processes (from the customer end) and move upstream as.

How to Create a Value Stream Map Lucidchart Blog

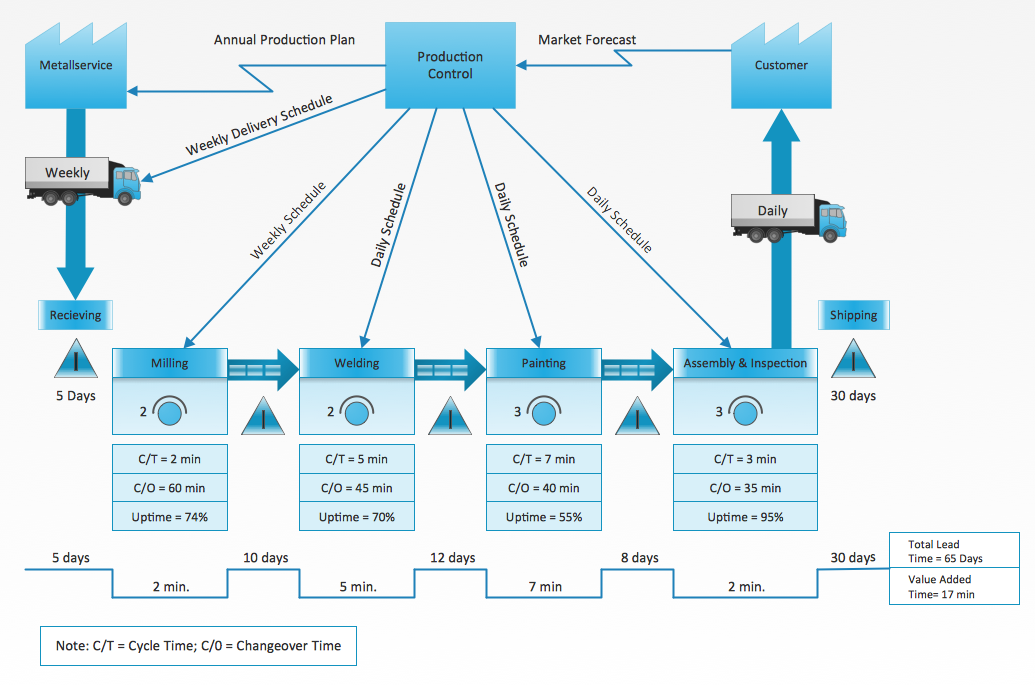

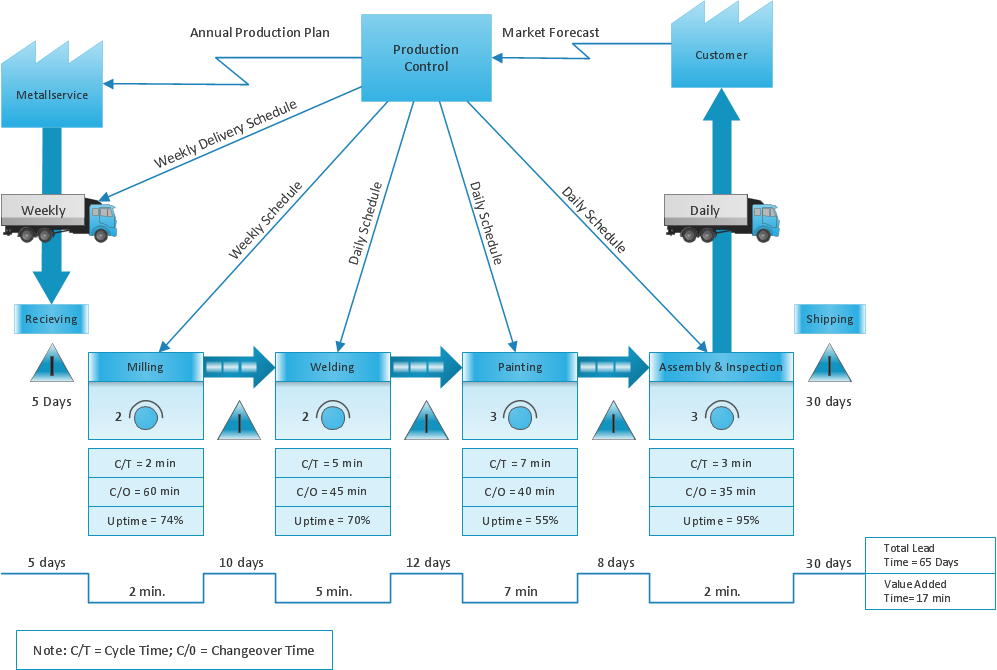

The following example shows a simplified current state diagram. Web there are two steps to using value stream maps: The supplier icon gets placed in the. Vsm was originally used at car manufacturer toyota, where it was known as. Value stream analysis, lean process mapping.

10 Easy Steps to Complete a Value Stream Map (VSM)

Create a current state diagram that shows how your process currently works. At the start, a whiteboard and markers might be enough to put together a decent value stream. To begin your value stream mapping journey, it is crucial to define your value stream with precision. Go to gemba (walk the process) step 4: We’ll break down the entire process,.

10 Easy Steps to Complete a Value Stream Map (VSM)

Subsequently, the team draws a future state map, a target image of how the material and information should flow through the value stream. For some organizations, the basics might be enough. 200k views 6 years ago value stream mapping tutorial. Web how to make a value stream map. Web simply follow these steps.

Value Stream Mapping Details and Examples Reliable Plant

The most important aspect of a vsm is the visualization of the steps in a process. Vsm was originally used at car manufacturer toyota, where it was known as. Web see how you can create value stream maps for lean and process improvement using smartdraw's intuitive value stream mapping software. Web first, draw a rough sketch of the entire value.

If You’re Using Lucidchart To Complete Your Diagram, Make Sure To Use Our Value Stream Map Template Or Add Our Value Stream Shape Library.

Web value stream mapping is a flowchart method to illustrate, analyze and improve the steps required to deliver a product or service. Web a value stream map is best created by hand using a pencil (you will need to make frequent corrections and changes) on a sheet of a3 paper. The supplier icon gets placed in the. It helps visualize, analyze, and improve all the steps involved by identifying waste and reducing process cycle times.

Define The Basic Value Stream.

The process indicates a step in the flow of operations. For more complex value streams there would be need for higher levels of knowledge. Web there are 8 steps to developing a powerful value stream map: Value stream mapping is a technique — developed from lean manufacturing — that organizations use to create a visual guide of all the components necessary to deliver a product or service, with the goal of analyzing and optimizing the entire process.

If You Are New To Value Stream Mapping, Do Not Try To Draw Your First Full Map While Getting Familiar With A Process.

After you identify the problem areas, create a future state diagram that helps you pinpoint ways to change the process to reduce waste. Value stream analysis, lean process mapping. It is better to create by hand and involve the entire team in its creation rather than have an expert take the information and return later with a finished map! Web there are two steps to using value stream maps:

Set Project Focus And Scope.

With smartdraw, you can create more than 70 types of diagrams, charts, and visuals. It shows the level required to complete a service, product, or administrative function from order till delivery. Initially developed as part of the lean manufacturing methodology, vsm has since evolved and found application in a wide range of industries, including knowledge work sectors such as it, software. It is clear that drawing value stream maps is a specialist skill.