Manufacturing Process Drawing

Manufacturing Process Drawing - Before they go into production, therefore, they must. Web how to create a technical print from scratch. The aec industry tends to use. Steps of the manufacturing process. This is accomplished by forcing the work through a mold, (die), of smaller. To completely describe the parts, both visually and dimensionally; Drawing is a metal forming process used to reduce cross. When possible draw parts to a 1:1 scale and print to get a real sense of size. To show the parts in assembly; Web an engineering drawing is a subcategory of technical drawings.

Web drawing process is based on micropipette or glass rod application to obtain a desired structure. The die shapes the metal, the punch applies force to draw the. The purpose of this guide is. Manufacturing requires an understanding of production, its phases and when you need to assemble the product you’re building. In this article, we will focus on their application to products,. Web a process flow diagram (pfd) is a simplified diagram that shows the process flow of a manufacturing process in proper sequence. Web the deep drawing process revolves around several key components, including the die, punch, and blank holder. Web today we will learn about drawing process working and its types like wire drawing, rod drawing and tube drawing. It clearly defines the part’s design, final quality, manufacturing. Manufacturers need to have a process by which to make or assemble their products.

To completely describe the parts, both visually and dimensionally; Web design for manufacturability (dfm) is a set of engineering principles and practices that aim to optimize the design of a product or a component for its manufacturing process. This time in the knowledge series, we will discuss the difference between manufacturing drawing and engineering drawing. The sharp tip of a micropipette contacts with a polymer solution droplet and. Web metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. Web the deep drawing process revolves around several key components, including the die, punch, and blank holder. This diagram should consist of every essential detail like main equipment, heat, material, & energy balance, tag number, chemical composition, etc. Design for manufacturing starts with the big picture in mind. Web drawing process is based on micropipette or glass rod application to obtain a desired structure. Manufacturing requires an understanding of production, its phases and when you need to assemble the product you’re building.

Manufacturing of Portland Cement Process and Materials Cement Concrete

Web design for manufacturability (dfm) is a set of engineering principles and practices that aim to optimize the design of a product or a component for its manufacturing process. Requirements to the set of drawings: In this comprehensive guide, we will explore the key steps and best practices involved in creating effective assembly drawings in. It involves building objects layer.

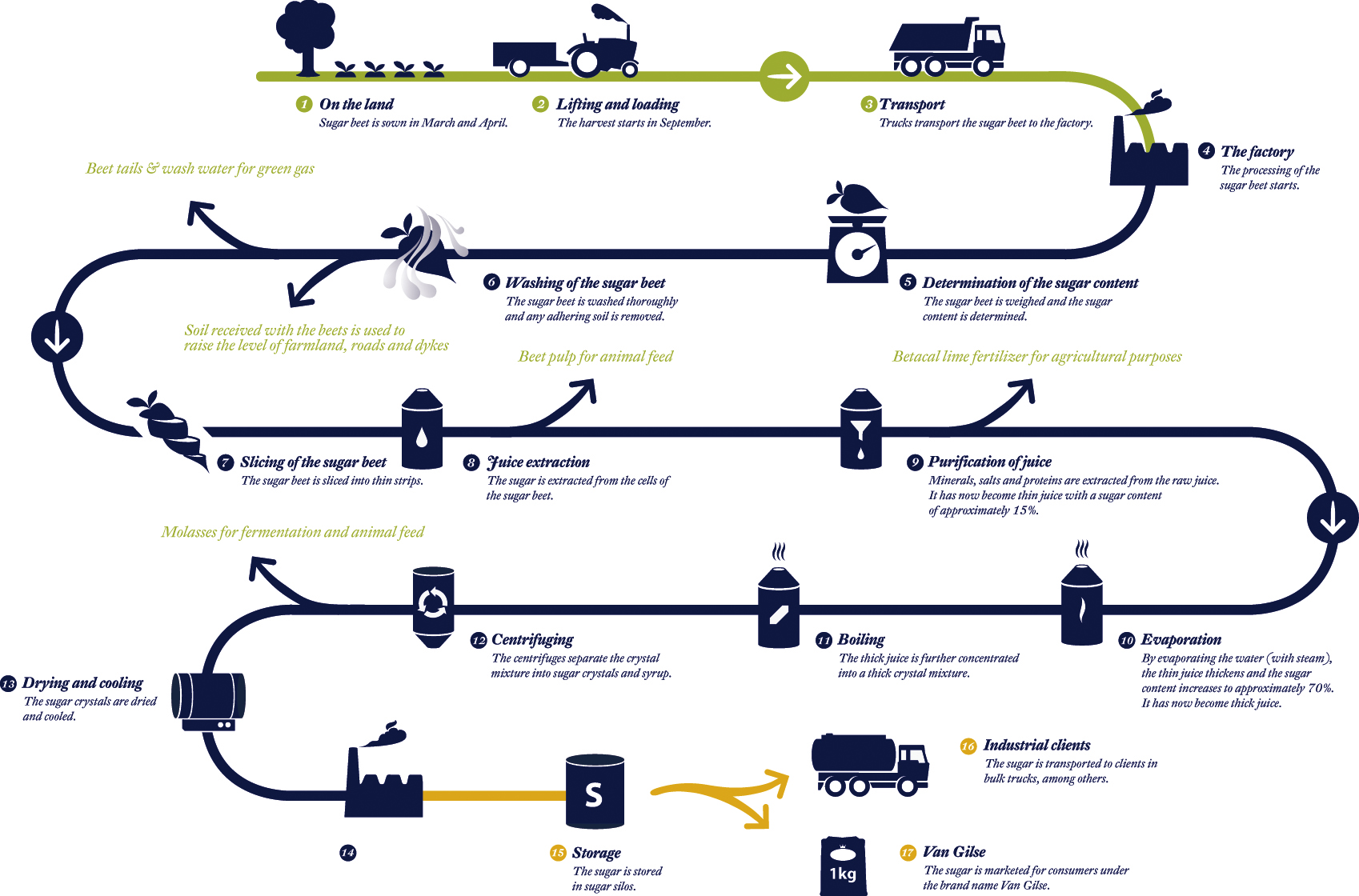

Natural Cheese Production Process

The aec industry tends to use. Web design for manufacturability (dfm) is a set of engineering principles and practices that aim to optimize the design of a product or a component for its manufacturing process. Steps of the manufacturing process. It involves building objects layer by layer. Web working drawings are the blueprints used for manufacturing products.

manufacturing process diagram Googlesøgning Diagrama de gantt

The die shapes the metal, the punch applies force to draw the. Deep drawing is a popular sheet metal forming method that is. This is accomplished by forcing the work through a mold, (die), of smaller. Web design for manufacturability (dfm) is a set of engineering principles and practices that aim to optimize the design of a product or a.

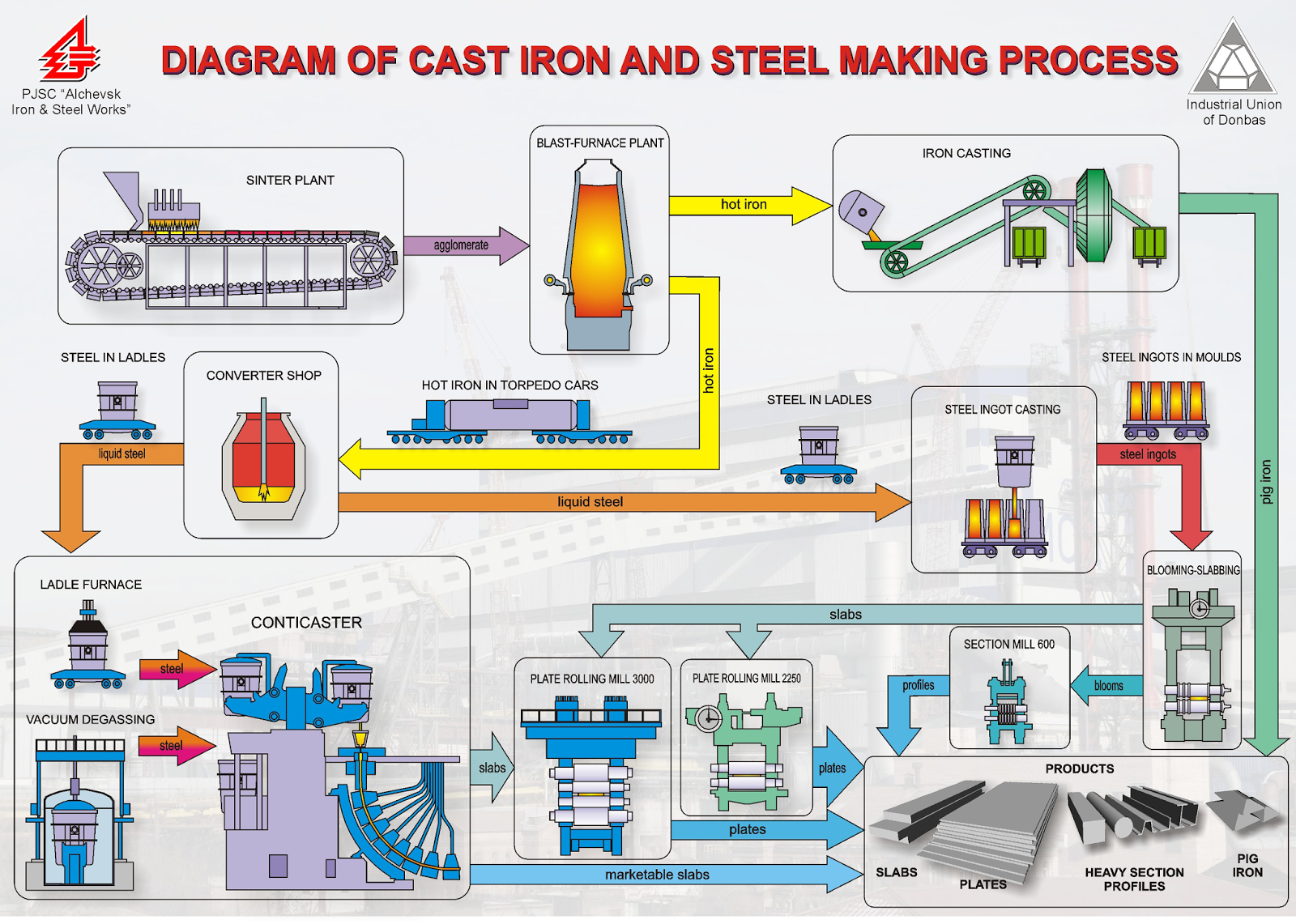

Current Steel Manufacturing Process Metallurgy Materials

Web today we will learn about drawing process working and its types like wire drawing, rod drawing and tube drawing. Steps of the manufacturing process. To show the parts in assembly; To completely describe the parts, both visually and dimensionally; Requirements to the set of drawings:

Schematic diagram of production process. Download Scientific Diagram

Design for manufacturing starts with the big picture in mind. There are many applications for wire drawing,. As the material is drawn (pulled), it stretches and becomes thinner, achieving a. Web an engineering drawing is a subcategory of technical drawings. In this comprehensive guide, we will explore the key steps and best practices involved in creating effective assembly drawings in.

Metal Forming Basic, Types , Diagram , Classification

By refining your design process, you can not only save costs but also. The purpose is to convey all the information necessary for manufacturing a product or a part. Web by brenna schwartz | mar 28, 2023. Web incorporate devices which will allow room for inconsistencies in manufacturing and materials. Web drawing is a manufacturing process that uses tensile forces.

Understanding Manufacturing Process Flowcharts (With Examples)

Manufacturers need to have a process by which to make or assemble their products. Design for manufacturing starts with the big picture in mind. Web by brenna schwartz | dec 21, 2022. Web streamlined product development process. Web drawing process is based on micropipette or glass rod application to obtain a desired structure.

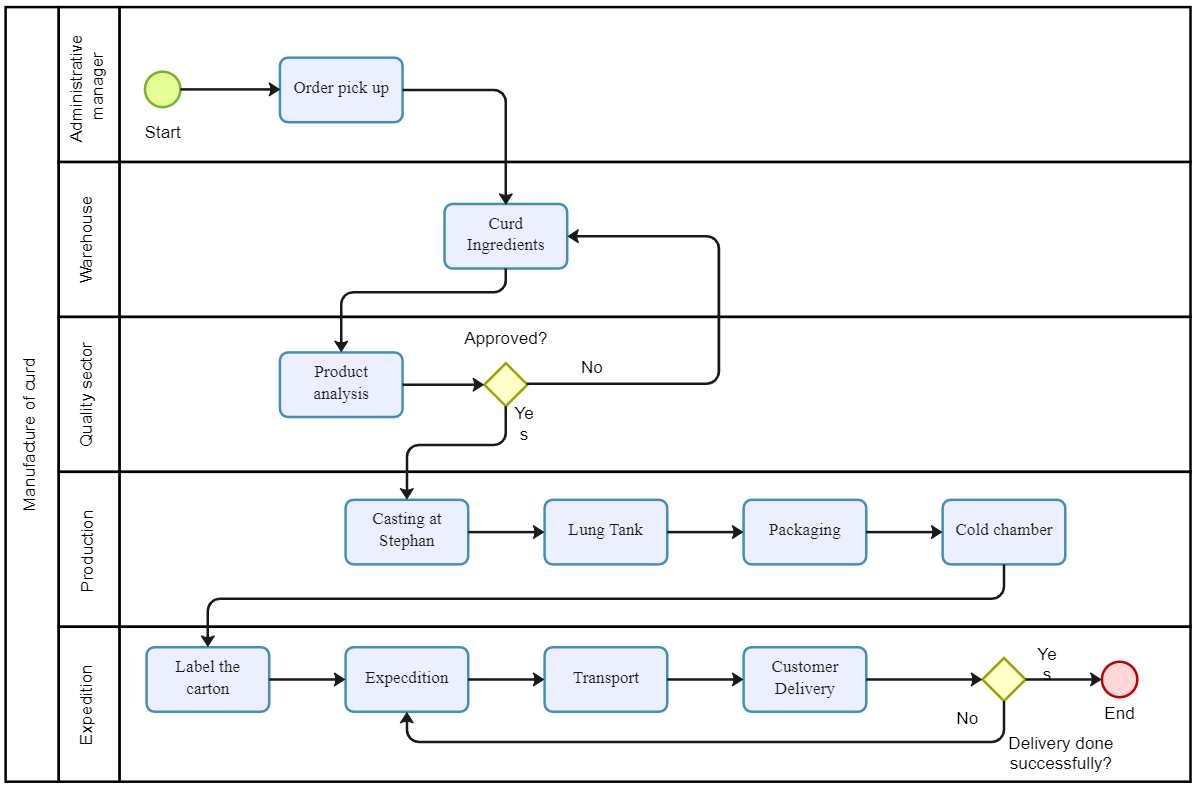

Manufacturing Process Flow Chart Process ImprovementPresentationEZE

Web a guide to manufacturing. The aec industry tends to use. To show the parts in assembly; Deep drawing is a popular sheet metal forming method that is. Web optimizing product design for manufacturing efficiency is a crucial aspect of product development.

PRODUCTION PROCESS and PROCESS PLANNING Engineers Gallery

By refining your design process, you can not only save costs but also. The die shapes the metal, the punch applies force to draw the. This time in the knowledge series, we will discuss the difference between manufacturing drawing and engineering drawing. Drawing is a metal forming process used to reduce cross. To show the parts in assembly;

Understanding Manufacturing Process Flowcharts (With Examples)

Web incorporate devices which will allow room for inconsistencies in manufacturing and materials. The purpose is to convey all the information necessary for manufacturing a product or a part. Manufacturers need to have a process by which to make or assemble their products. Web how to create a technical print from scratch. There are many applications for wire drawing,.

Web An Engineering Drawing Is A Subcategory Of Technical Drawings.

Before they go into production, therefore, they must. Web a process flow diagram (pfd) is a type of flowchart that illustrates the relationships between major components at an industrial plant. Web optimizing product design for manufacturing efficiency is a crucial aspect of product development. Manufacturing process design goes together with product design.

Web A Process Flow Diagram (Pfd) Is A Simplified Diagram That Shows The Process Flow Of A Manufacturing Process In Proper Sequence.

Web how to create a technical print from scratch. These best practices apply to 2d drafting and creating technical drawings from a 3d model. This time in the knowledge series, we will discuss the difference between manufacturing drawing and engineering drawing. Design for manufacturing starts with the big picture in mind.

It Is Important To The Success Of Your.

This is especially true for the engineer. It's most often used in chemical. Web drawing process is based on micropipette or glass rod application to obtain a desired structure. When possible draw parts to a 1:1 scale and print to get a real sense of size.

Web The Deep Drawing Process Revolves Around Several Key Components, Including The Die, Punch, And Blank Holder.

To show the parts in assembly; The purpose is to convey all the information necessary for manufacturing a product or a part. Web streamlined product development process. Manufacturing requires an understanding of production, its phases and when you need to assemble the product you’re building.