Moulds Drawing

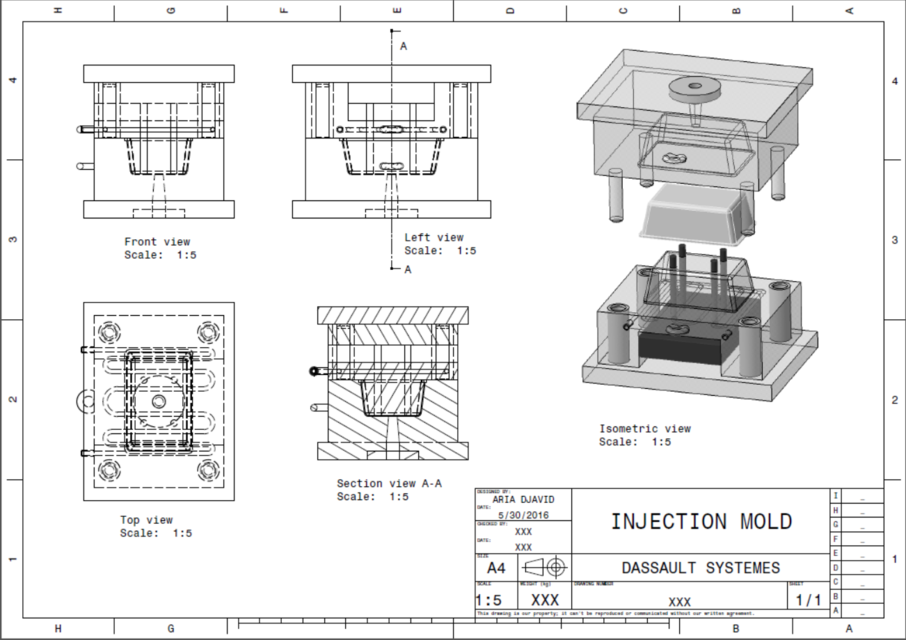

Moulds Drawing - Once the product design has been finalized, the next step is to design the blow mold. We are going to look at the things that one has to consider when mold drawing and designing or injection molding process and how each of these considerations affects the final end product. 929 views 4 years ago #solidworks #solidworkstutorial. This type of drawing is often used in the manufacturing industry to develop prototypes of ongoing products in a plan using a mould. The role of an injection molding dfm report. Placement of lifters and sliders. You can create these drawings by hand or with any cad tool. Web a cad drawing is a digital drawing showing your design in either 2d or 3d format. Contact us today to start your custom molding project. Web the injection mold design tutorial is the best guide there is for the money.

This is vital since it provides a way of ensuring there are no defects or issues that may arise on the final mold after manufacturing. To see this branch, follow this link. Web plastic injection molding is the preferred process for manufacturing plastic parts. The role of an injection molding dfm report. Web a cad drawing is a digital drawing showing your design in either 2d or 3d format. Placement of lifters and sliders. 929 views 4 years ago #solidworks #solidworkstutorial. Web the design of the main components of an injection mold will be discussed and good design practices, rules of thumb, and key calculations will be shared. 40 views 2 months ago. Web injection mold standard, mold series, common mold steels and applications, drawing format and standards, geometry format, construction, and standards.

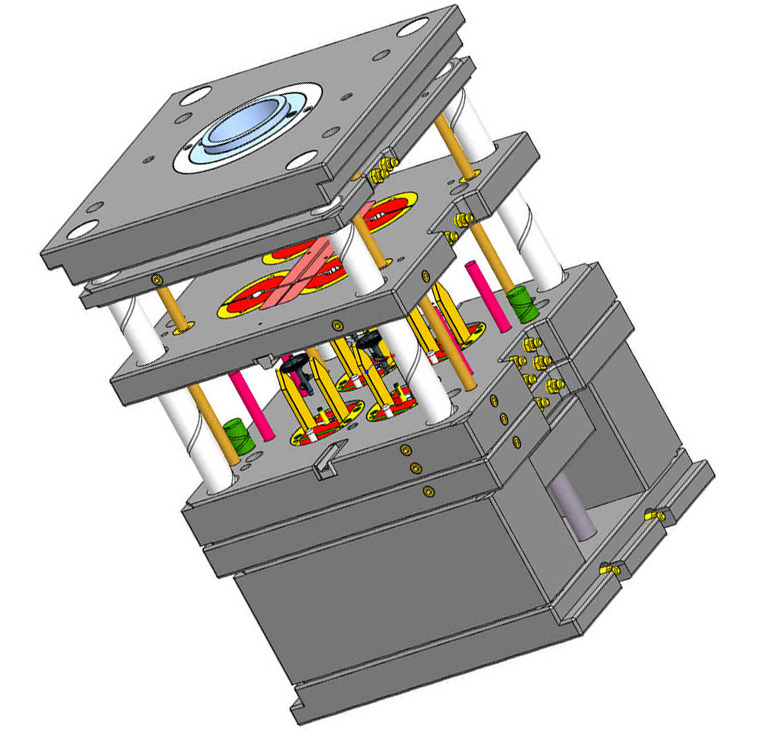

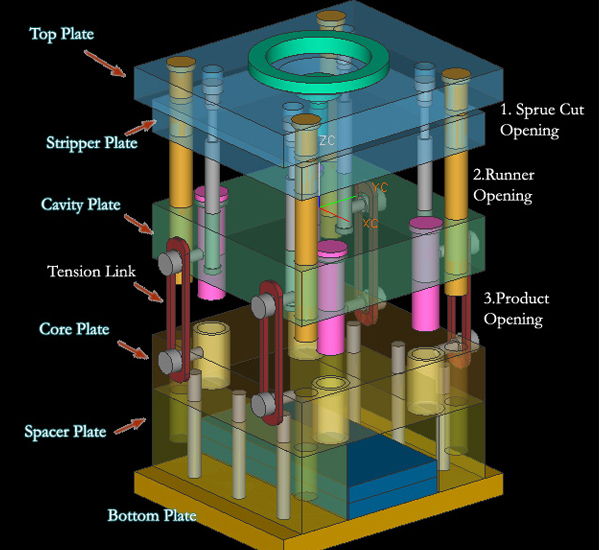

Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. Having a proper tool design review and checklist can and will save time to market. Contact us today to start your custom molding project. 929 views 4 years ago #solidworks #solidworkstutorial. Web in this video, you’ll learn the fundamentals of mold design. First, ensure you have a solid object, rather than abutting surfaces. Web what is an injection molding dfm (design for manufacturing) report? Injection mold design the following information defines the minimum requirements for upmold injection molds produced by upmold engineering. Placement of lifters and sliders. This includes creating 2d or 3d drawings of the mold, determining the number of cavities needed, and deciding on the type of mold (single or.

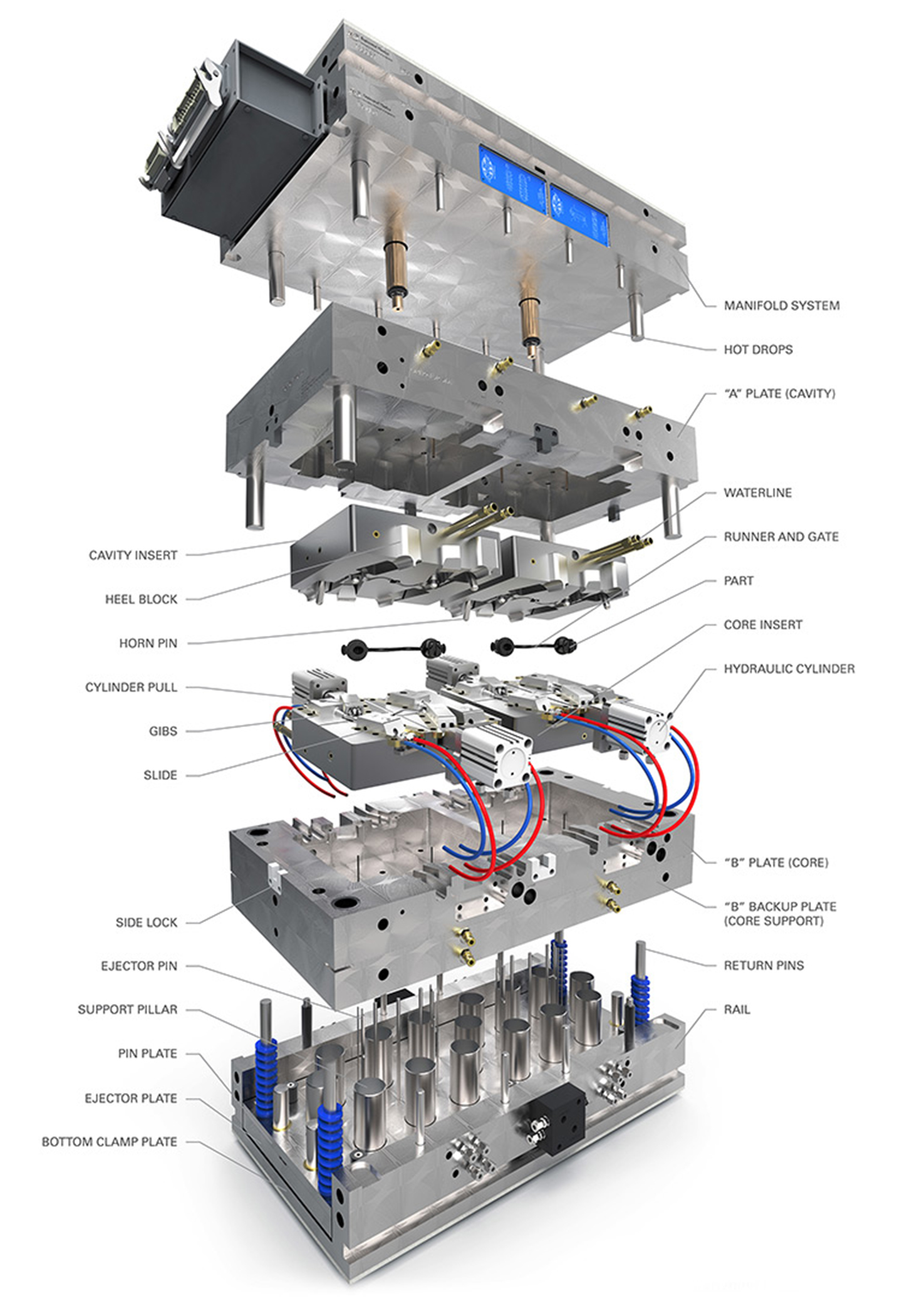

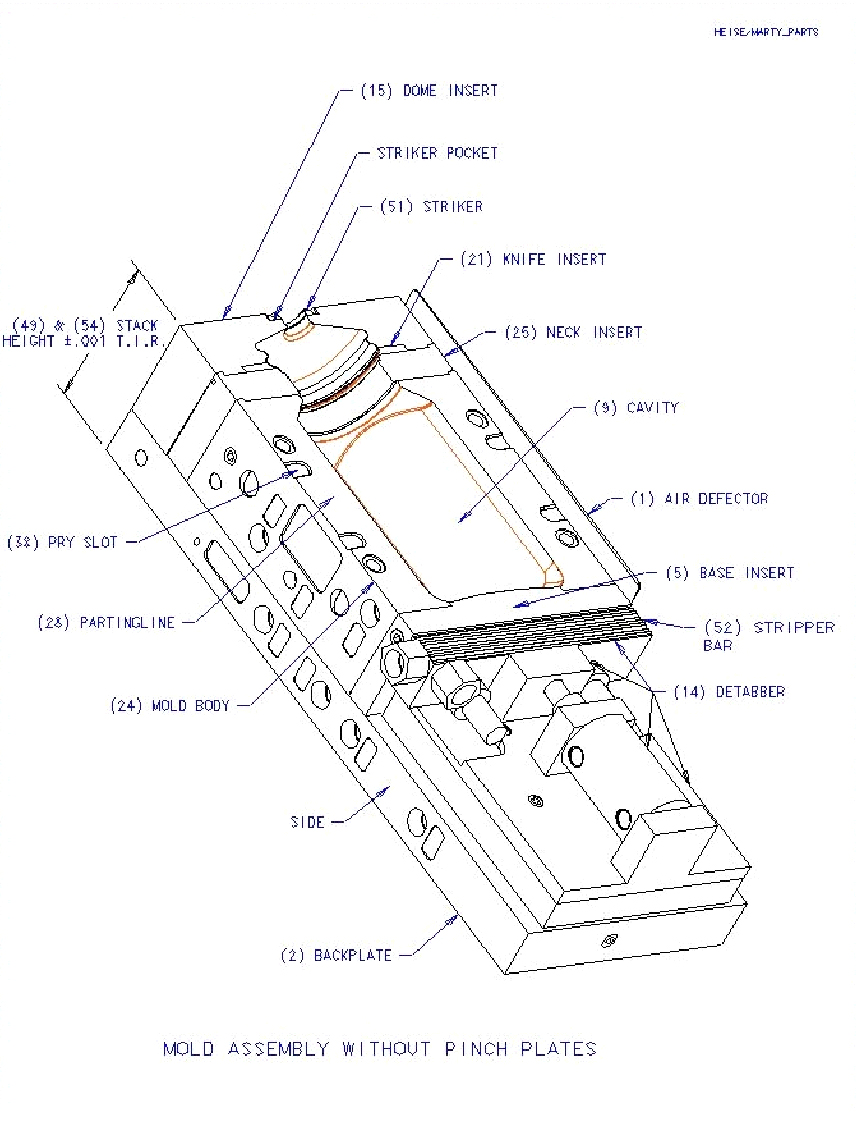

Anatomy of a Mold PTI Engineered Plastics, Inc.

929 views 4 years ago #solidworks #solidworkstutorial. This includes creating 2d or 3d drawings of the mold, determining the number of cavities needed, and deciding on the type of mold (single or. This section will guide you through the essential tools and materials required for mold making. We are going to look at the things that one has to consider.

Mold Drawing at GetDrawings Free download

To see this branch, follow this link. A design branch showing the surfacing required to accomplish a proper mold split. Ejector pins type and locations. We are going to look at the things that one has to consider when mold drawing and designing or injection molding process and how each of these considerations affects the final end product. Typical contents.

Schematic drawing of the mold for an injection molding process. The

Typical contents of a dfm report. This includes creating 2d or 3d drawings of the mold, determining the number of cavities needed, and deciding on the type of mold (single or. To see this branch, follow this link. Web the injection mold design tutorial is the best guide there is for the money. Web the mold structure drawing typically includes.

Injection Molding Mold Design Tutorial Mold design Guidance Upmold

Web how to draw bread mould#breadmould #mould #drawingeasy This type of drawing is often used in the manufacturing industry to develop prototypes of ongoing products in a plan using a mould. The role of an injection molding dfm report. Web what is an injection molding dfm (design for manufacturing) report? Web a cad drawing is a digital drawing showing your.

Inhouse mold making design for precision plastics

Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. A design branch showing the surfacing required to accomplish a proper mold split. Web one area that manufacturers and mold engineers have to consider deeply is the mold drawing, which is basically the creation of.

MOLD DESIGN How to Draw BLOW MOLD for Jerry Can 1 Liter SOLIDWORKS

To see this branch, follow this link. Web in this video, you’ll learn the fundamentals of mold design. Placement of lifters and sliders. This section will guide you through the essential tools and materials required for mold making. 40 views 2 months ago.

Mold Drawing at Explore collection of Mold Drawing

A design branch showing the surfacing required to accomplish a proper mold split. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. Web the mold structure drawing typically includes a front view, top view, and side view, providing a complete view of the mold’s.

Mold Drawing at GetDrawings Free download

Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. 929 views 4 years ago #solidworks #solidworkstutorial. Part drawings are essential because they provide a detailed view of each part of the mold, including dimensions, tolerances, and surface finishes. Web gathering materials for mold making..

Six Points Of Preparation For Mold Assembly China Plastic Injection

Ejector pins type and locations. Web a cad drawing is a digital drawing showing your design in either 2d or 3d format. Web the mold structure drawing typically includes a front view, top view, and side view, providing a complete view of the mold’s structure. Part drawings are essential because they provide a detailed view of each part of the.

How to Design for Injection Moulding MADE Products

Once the product design has been finalized, the next step is to design the blow mold. Typical contents of a dfm report. Web plastic injection molding is the preferred process for manufacturing plastic parts. This will make it easy to separate the mold into several pieces at the appropriate time. First, ensure you have a solid object, rather than abutting.

Typical Contents Of A Dfm Report.

First, ensure you have a solid object, rather than abutting surfaces. This is vital since it provides a way of ensuring there are no defects or issues that may arise on the final mold after manufacturing. Injection mold design the following information defines the minimum requirements for upmold injection molds produced by upmold engineering. Web one area that manufacturers and mold engineers have to consider deeply is the mold drawing, which is basically the creation of the mould design blueprint.

40 Views 2 Months Ago.

Web the mold structure drawing typically includes a front view, top view, and side view, providing a complete view of the mold’s structure. Web what is an injection molding dfm (design for manufacturing) report? Once the product design has been finalized, the next step is to design the blow mold. Ejector pins type and locations.

It Provides A Detailed Way Or Like A Sample Of Visualizing The Mold To Be Built.

Part drawings are essential because they provide a detailed view of each part of the mold, including dimensions, tolerances, and surface finishes. This type of drawing is often used in the manufacturing industry to develop prototypes of ongoing products in a plan using a mould. Web the injection mold design tutorial is the best guide there is for the money. Before starting the mold making process, it's crucial to gather all the necessary materials.

The Grabcad Library Offers Millions Of Free Cad Designs, Cad Files, And 3D Models.

Whether you're a beginner or an experienced artist, our guide will help you master the art. We are going to look at the things that one has to consider when mold drawing and designing or injection molding process and how each of these considerations affects the final end product. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. This section will guide you through the essential tools and materials required for mold making.