P And Id Drawing

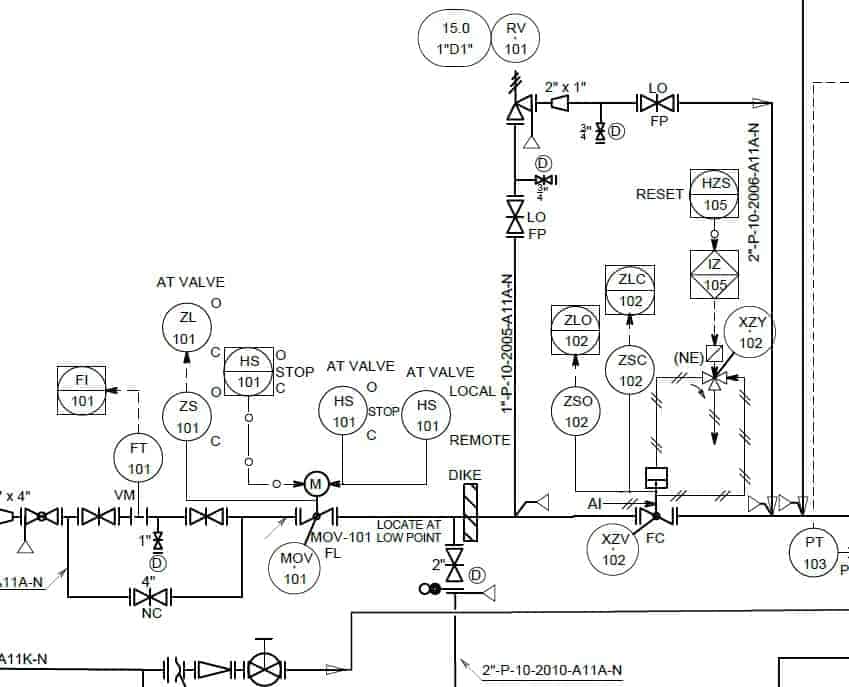

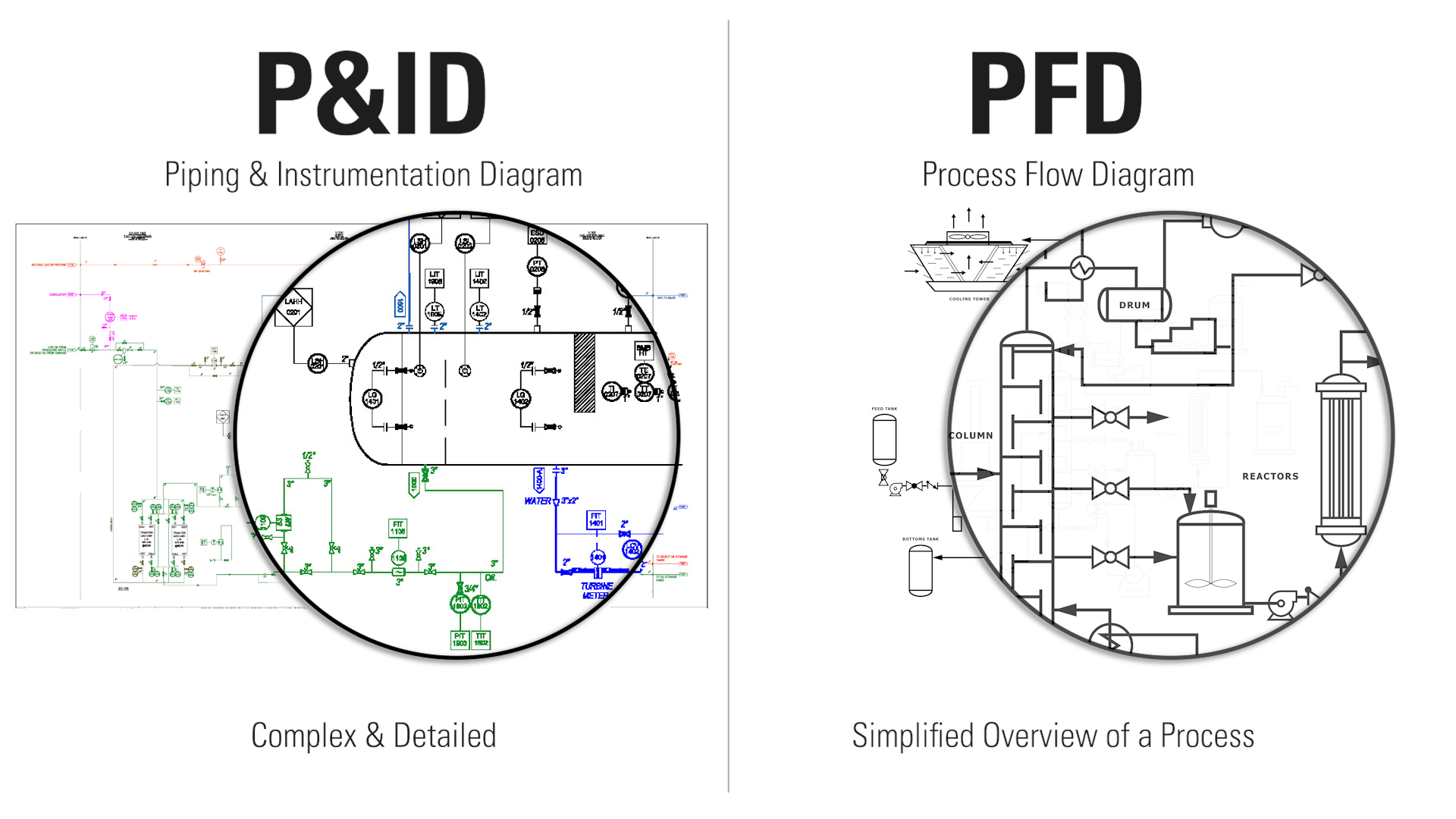

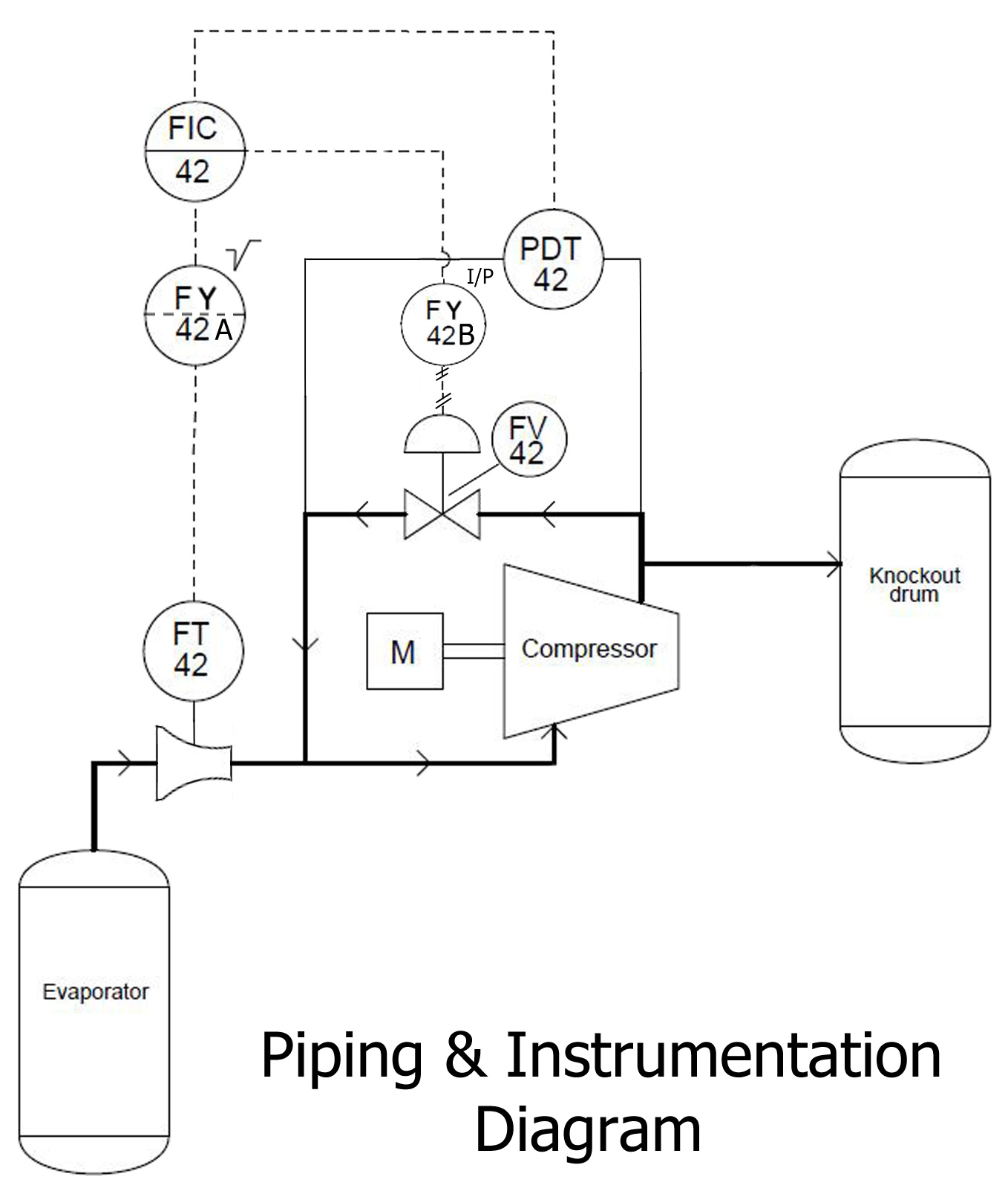

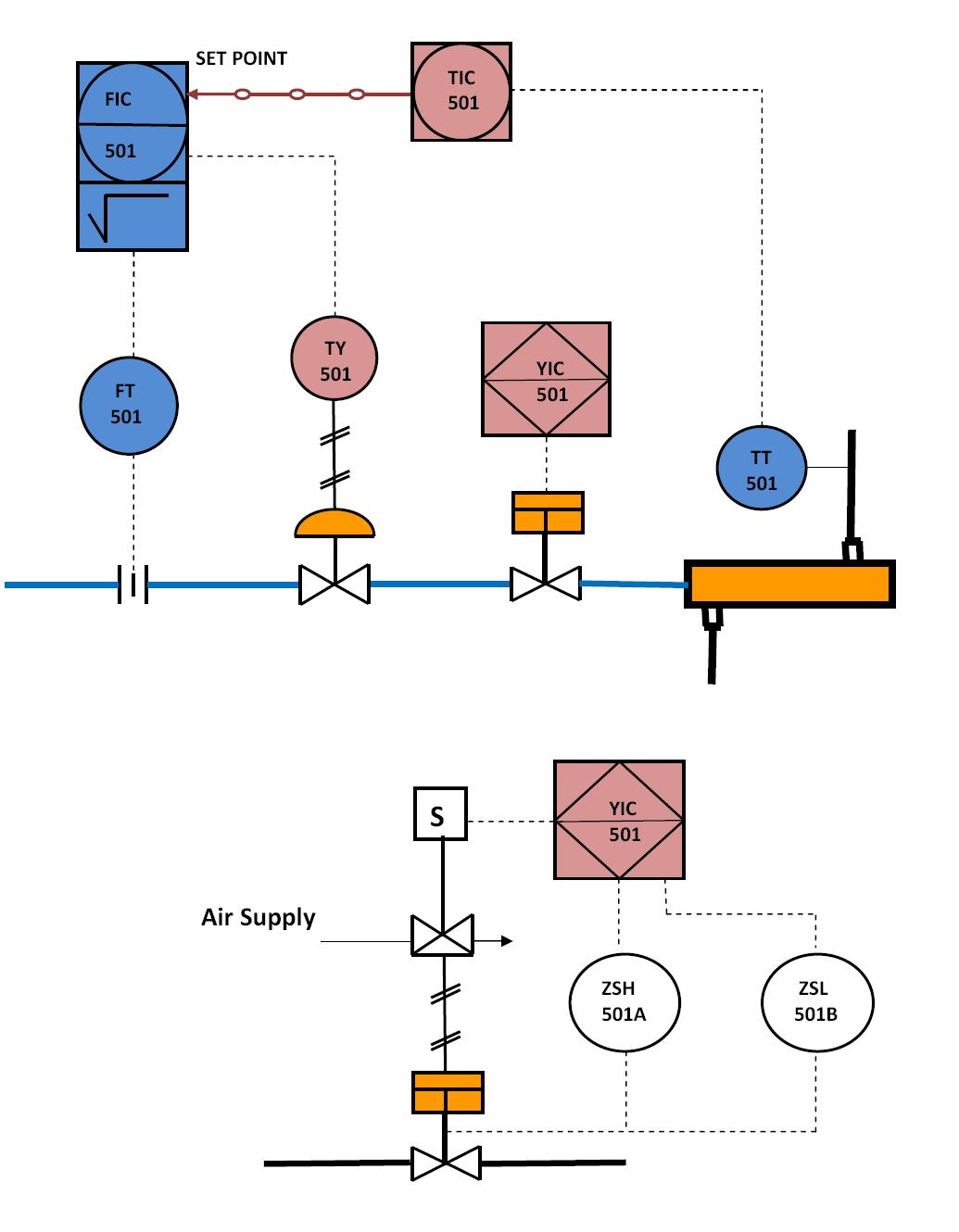

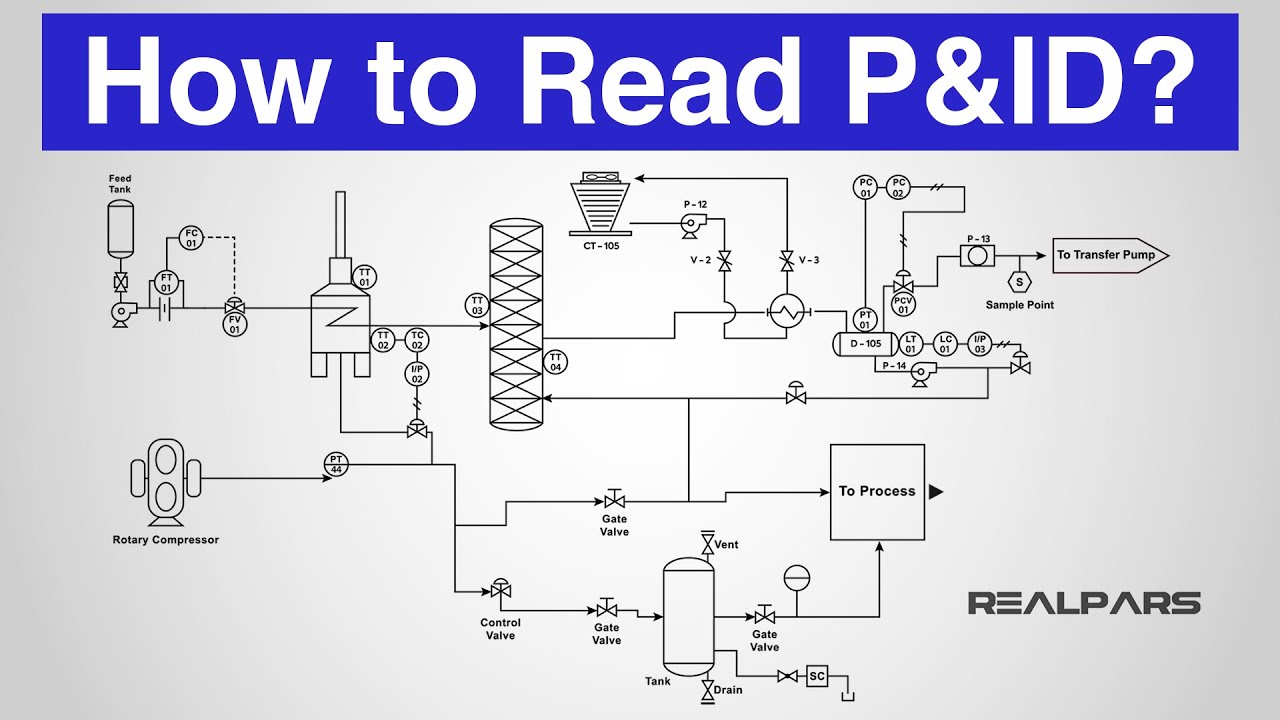

P And Id Drawing - These symbols can represent actuators, sensors, and controllers and may be apparent in most, if not all, system diagrams. Standard structures located on a p&id include storage tanks, surge tanks, pumps, heat exchangers, reactors, and distillation columns. Web what is a p&id drawing? Only a few steps to follow to create a p&id diagram, but one who does it should know well knowledge about the plant process. Luffy, a boy whose body gained the properties of rubber after unintentionally eating a devil fruit, is inspired by his childhood idol, the powerful pirate red haired shanks, to set off on a journey from the east blue sea to find the legendary one piece treasure and proclaim him. Web visual paradigm's p&id tool features a handy diagram editor that allows you to draw p&id diagrams, industrial diagrams, and schematics quickly and easily. Web a piping and instrumentation diagram (p&id or pid) is a detailed diagram in the process industry which shows the piping and process equipment together with the instrumentation and control devices. P&id is more complex than pfd and includes lots of details, because of th. Web p&id drawing is a schematic representation of instrumentations, control systems, and pipelines used in any process development plant. Web in this video, you will learn the basics of piping and instrumentation diagrams (also called p&id drawings).#pipingandinstrumentation #processcontrol #instru.

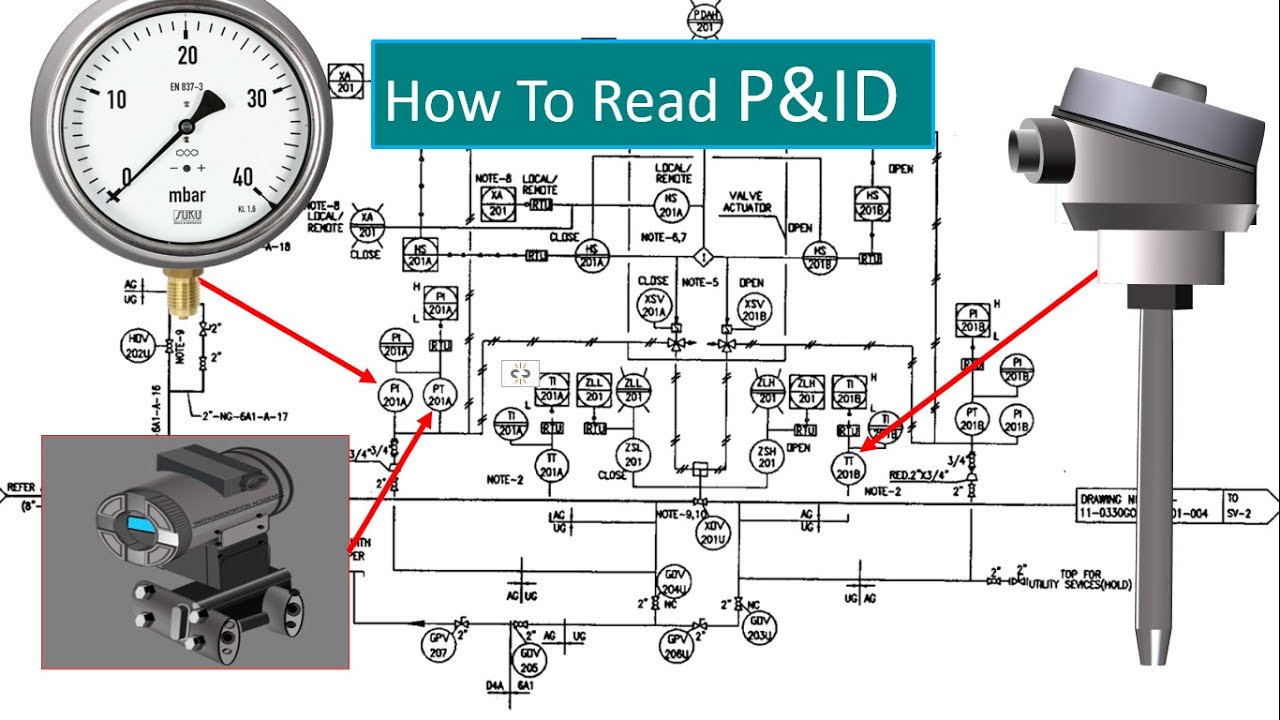

Piping and instrumentation diagrams are typically created by engineers who are designing a manufacturing process for a physical plant. These symbols can represent actuators, sensors, and controllers and may be apparent in most, if not all, system diagrams. Web visual paradigm's p&id tool features a handy diagram editor that allows you to draw p&id diagrams, industrial diagrams, and schematics quickly and easily. Before sketching your p&id, it's much better to make a list of all elements that you need. Web p&ids are a schematic illustration of the functional relationship of piping, instrumentation and system equipment components used in the field of instrumentation and control or automation. Make your own p&id diagrams with this free online drawing tool. Only a few steps to follow to create a p&id diagram, but one who does it should know well knowledge about the plant process. Piping and instrumentation diagrams (p&ids) use specific symbols to show the connectivity of equipment, sensors, and valves in a control system. Web what is a p&id drawing? 357k views 3 years ago basic instrumentation through animation.

Web piping & instrumentation diagram explained. Web in this video, you will learn the basics of piping and instrumentation diagrams (also called p&id drawings).#pipingandinstrumentation #processcontrol #instru. A link to download this p&id is given at the end of the page. These facilities have complex chemical or mechanical components and processes, which are modeled with diagrams. All valves and their identifications. They offer a detailed overview of the process flow, including equipment, valves, and instrumentation, crucial for design and operational understanding. Web like other specialized diagrams, p&id's are comprised of standard shapes and symbols. They are typically created by engineers who are designing a manufacturing process for a physical plant. Process piping, sizes and identification. Web p&id drawing is a schematic representation of instrumentations, control systems, and pipelines used in any process development plant.

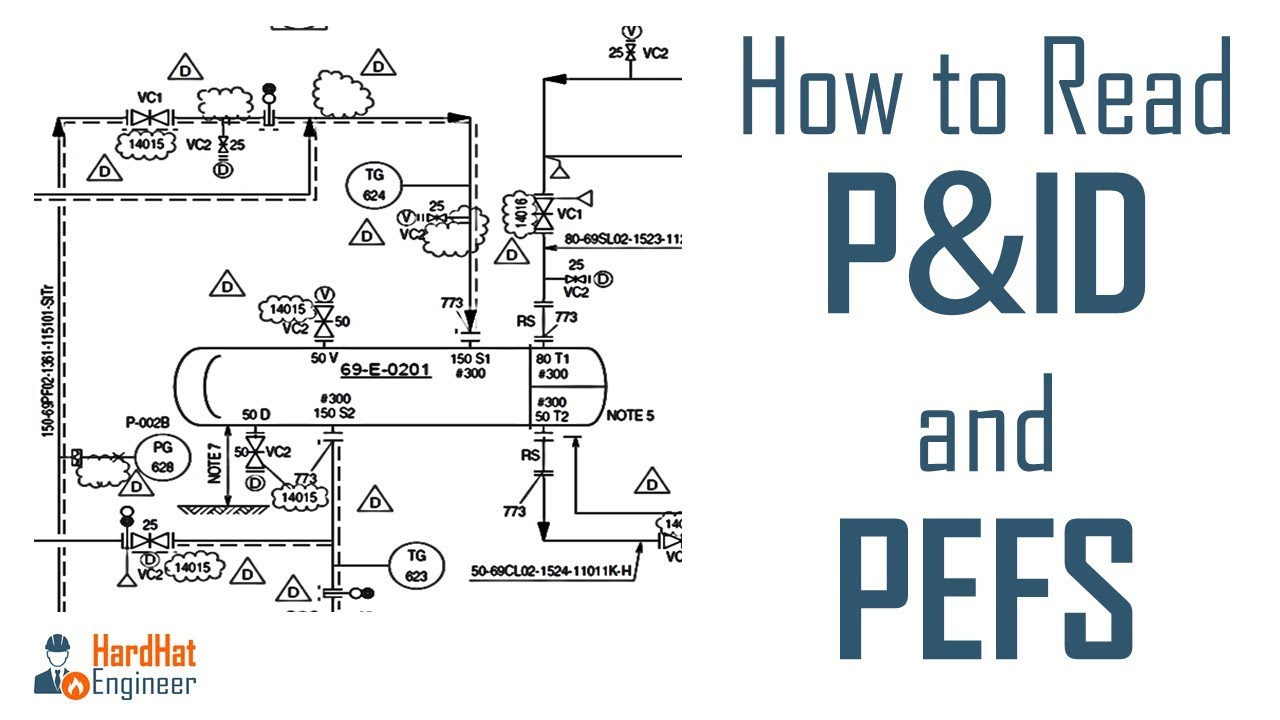

Learn How to Read P&ID Drawings A Complete Guide (2023)

Web you will learn how to read p&id and pefs with the help of the actual plant drawing. Create the full list of instruments and equipment required for the process. Watch the video as it has. To create such a comprehensive design, start by listing the elements in a standard p&id. Web you will learn how to read p&id and.

P & ID Diagram. How To Read P&ID Drawing Easily. Piping

It uses symbols to represent process equipment such as sensors and controllers. Web in this video, you will learn the basics of piping and instrumentation diagrams (also called p&id drawings).#pipingandinstrumentation #processcontrol #instru. It includes all piping, instruments, valves, and equipment the system consists of. All valves and their identifications. Web a piping & instrumentation diagram (p&id) is a schematic layout.

P&Id Symbol / Solved The P&ID Symbol Shown Represents This Equipment

Mechanical equipment with names and numbers. To create such a comprehensive design, start by listing the elements in a standard p&id. A link to download this p&id is given at the end of the page. Web a piping & instrumentation diagram (p&id) is a schematic layout of a plant that displays the units to be used, the pipes connecting these.

What is P&ID? (Piping and Instrumentation Diagram)? Synergy Codes

P&id is more complex than pfd and includes lots of details. Standard structures located on a p&id include storage tanks, surge tanks, pumps, heat exchangers, reactors, and distillation columns. Web p&ids are a schematic illustration of the functional relationship of piping, instrumentation and system equipment components used in the field of instrumentation and control or automation. They are typically created.

Piping and Instrumentation Documents Instrumentation Tools

Piping and instrumentation diagrams are typically created by engineers who are designing a manufacturing process for a physical plant. Web piping & instrumentation diagram explained. Web visual paradigm's p&id tool features a handy diagram editor that allows you to draw p&id diagrams, industrial diagrams, and schematics quickly and easily. To create such a comprehensive design, start by listing the elements.

How to Read P&ID Drawing A Complete Tutorial YouTube

P&id software built with engineers in mind. Web p&id diagrams (piping and instrumentation diagrams) provide a schematic representation of the functional relationship between piping, instrumentation, and system components within a project. All valves and their identifications. To create such a comprehensive design, start by listing the elements in a standard p&id. Piping and instrumentation diagrams (p&ids) use specific symbols to.

How to Read a P&ID Drawing Quickly and Easily Edraw Max

It uses symbols to represent process equipment such as sensors and controllers. It is the basic training document to explain the process details to operation guys, field engineers, and maintenance professionals. Piping and instrumentation diagrams (p&ids) use specific symbols to show the connectivity of equipment, sensors, and valves in a control system. Make your own p&id diagrams with this free.

How to Read and Interpret Piping and Instrumentation Diagrams (P&ID

It is also called as mechanical flow diagram (mfd). Process piping, sizes and identification. Web a piping & instrumentation diagram (p&id) is a schematic layout of a plant that displays the units to be used, the pipes connecting these units, and the sensors and control valves. To create such a comprehensive design, start by listing the elements in a standard.

Read P&ID Diagram. P&ID Drawings Explained. Read Piping

Web a piping and instrumentation diagram (p&id or pid) is a detailed diagram in the process industry which shows the piping and process equipment together with the instrumentation and control devices. Make your own p&id diagrams with this free online drawing tool. It uses symbols to represent process equipment such as sensors and controllers. A p&id uses simple graphics to.

How to Read a P&ID? (Piping & Instrumentation Diagram) YouTube

Web p&id drawing is a schematic representation of instrumentations, control systems, and pipelines used in any process development plant. Standard structures located on a p&id include storage tanks, surge tanks, pumps, heat exchangers, reactors, and distillation columns. Usually include the necessary equipment like pipes, instruments, valves, control devices, pumps, etc. P&id is more complex than pfd and includes lots of.

Piping And Instrumentation Diagrams Are Typically Created By Engineers Who Are Designing A Manufacturing Process For A Physical Plant.

Web a piping & instrumentation diagram (p&id) is a schematic layout of a plant that displays the units to be used, the pipes connecting these units, and the sensors and control valves. Only a few steps to follow to create a p&id diagram, but one who does it should know well knowledge about the plant process. Piping and instrumentation diagrams (p&ids) use specific symbols to show the connectivity of equipment, sensors, and valves in a control system. Standard structures located on a p&id include storage tanks, surge tanks, pumps, heat exchangers, reactors, and distillation columns.

Visualize And Understand Your Piping Structures And Processes.

Mechanical equipment with names and numbers. Your list should include all piping elements, including the order and placement of: Web different software is available to create or draw a p&id diagram. Watch the video as it has.

Before Sketching Your P&Id, It's Much Better To Make A List Of All Elements That You Need.

Web p&ids are a schematic illustration of the functional relationship of piping, instrumentation and system equipment components used in the field of instrumentation and control or automation. Luffy, a boy whose body gained the properties of rubber after unintentionally eating a devil fruit, is inspired by his childhood idol, the powerful pirate red haired shanks, to set off on a journey from the east blue sea to find the legendary one piece treasure and proclaim him. There's a huge variety of symbols, depending on industry and manufacturer, so we've created this guide to feature the most popular p&id symbols supported within our p&id software and is standardized for best practice across the industry. The mechanical and electrical details of a given system or process,

They Are Typically Created By Engineers Who Are Designing A Manufacturing Process For A Physical Plant.

Process piping, sizes and identification. P&ids are used to develop guidelines and standards for facility operation. List elements that you need. Create the full list of instruments and equipment required for the process.