Roll Form Tap Drill Chart

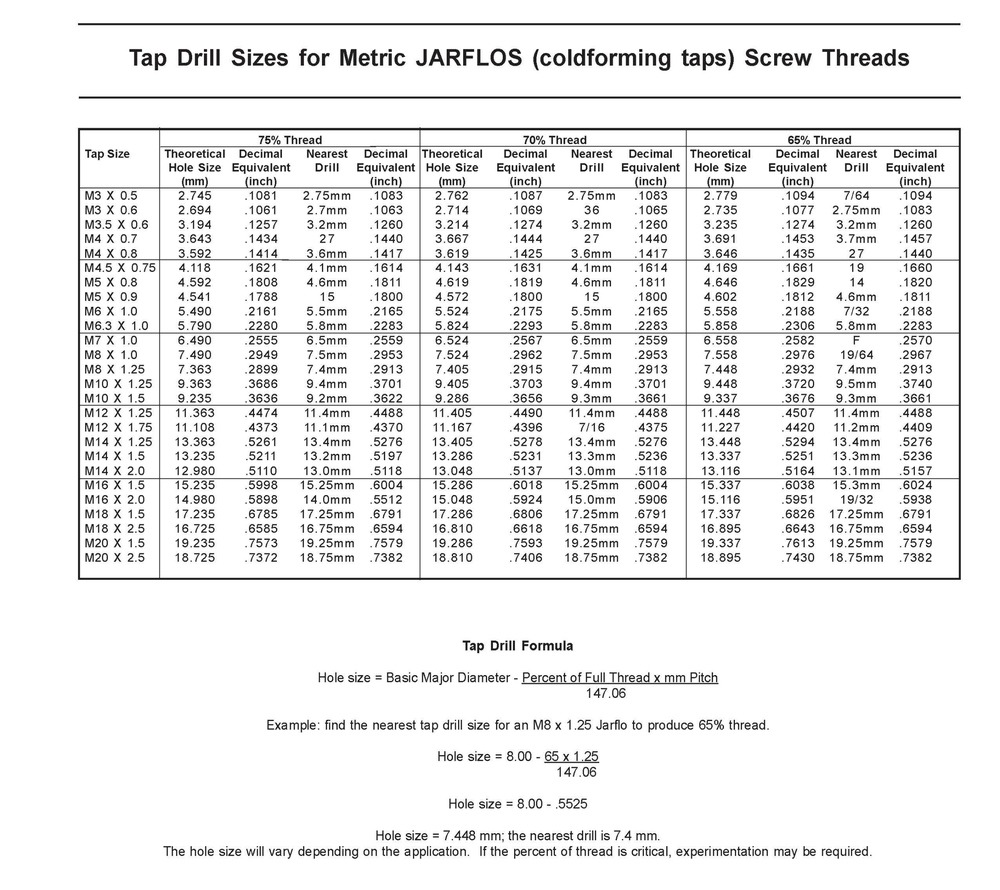

Roll Form Tap Drill Chart - — (.0068 x % of thread desired) threads per inch 068 x 250 — =.228 dia. (mm) — (% of thread desired x mm pitch) 147.06 (example m8 x 1.25 tap with 65% thread) = 8 — (65 x 1.25) = 7.45 mm. Web jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Special, super and titanium alloys. Hole size for metric cutting taps major diameter pitch % of thread hole size 3. Hole size for metric forming taps major diameter pitch % of thread hole size Tapping drill size since thread forming. Desired thread size and % of full thread are input parameters for the calculator. Web first, roll taps are chipless. Calculations are done according to roll form tap drill charts which are given in the machinery's handbook.

Web roll form tap drill chart calculator for calculation of recommended roll form tap drill sizes for unified threads. Hardened steel and chilled cast iron. Grey cast iron, malleable and spheroidal iron. Roll tapping is a process which forms a. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Web jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Hole size for inch cutting taps major diameter tpi (threads/inch) % of thread hole size 2. Special, super and titanium alloys. Because they do not remove material from the hole, form taps generate no chips that must be removed. — (.0068 x % of thread desired) threads per inch 068 x 250 — =.228 dia.

Calculations are done according to roll form tap drill charts which are given in the machinery's handbook. Web jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. But choose out of some of these chocolate may affect your browsing experience. Hole size for inch forming taps major diameter tpi (threads/inch) % of thread hole size 4. Because they do not remove material from the hole, form taps generate no chips that must be removed. Hardened steel and chilled cast iron. Hole size for inch cutting taps major diameter tpi (threads/inch) % of thread hole size 2. Desired thread size and % of full thread are input parameters for the calculator. Roll tapping is a process which forms a. Such cookies will be stored are own browser only with your consent.

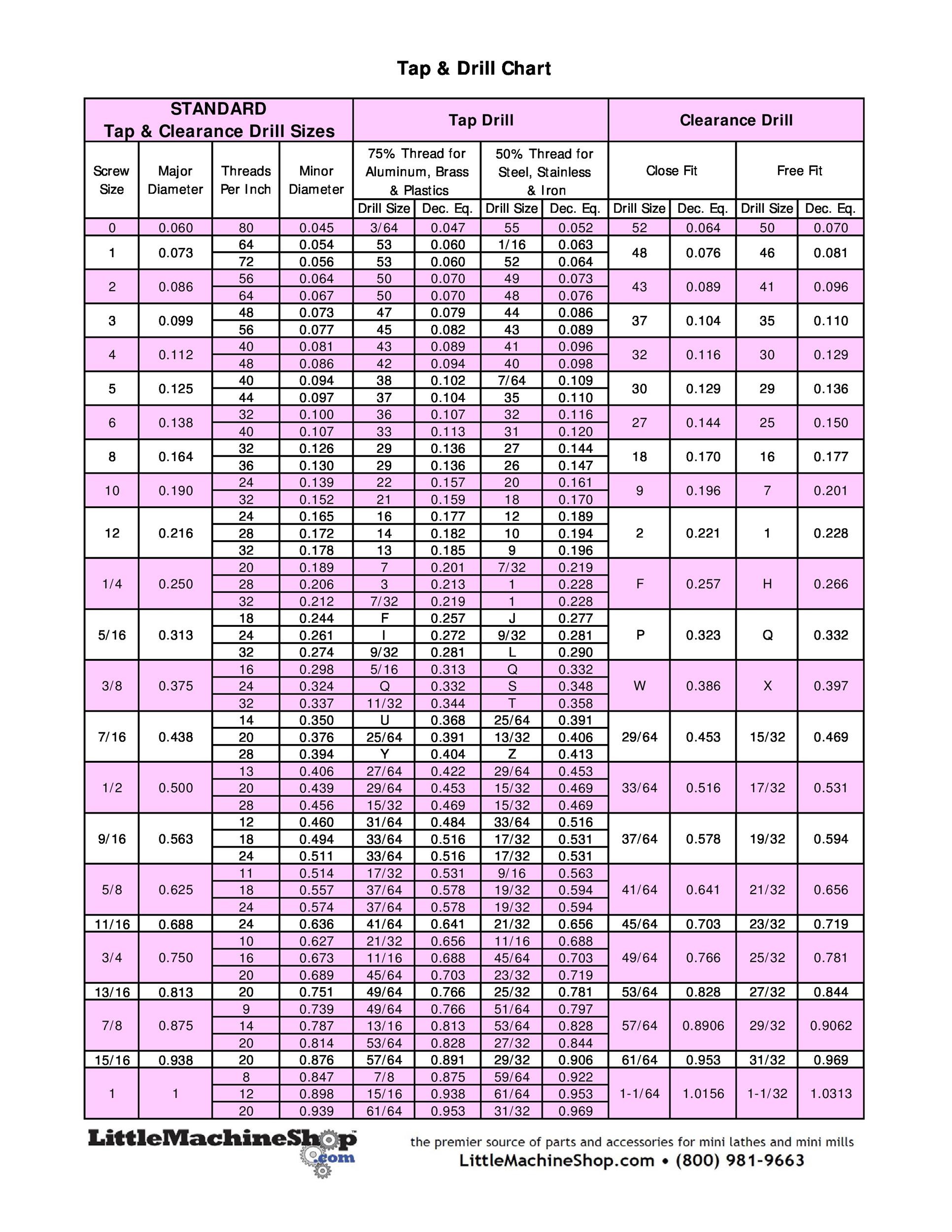

23 Printable Tap Drill Charts [PDF] Template Lab

Desired thread size and % of full thread are input parameters for the calculator. Web roll form tap drill chart calculator for calculation of recommended roll form tap drill sizes for unified threads. Tapping drill size since thread forming. Hole size for metric cutting taps major diameter pitch % of thread hole size 3. Web first, roll taps are chipless.

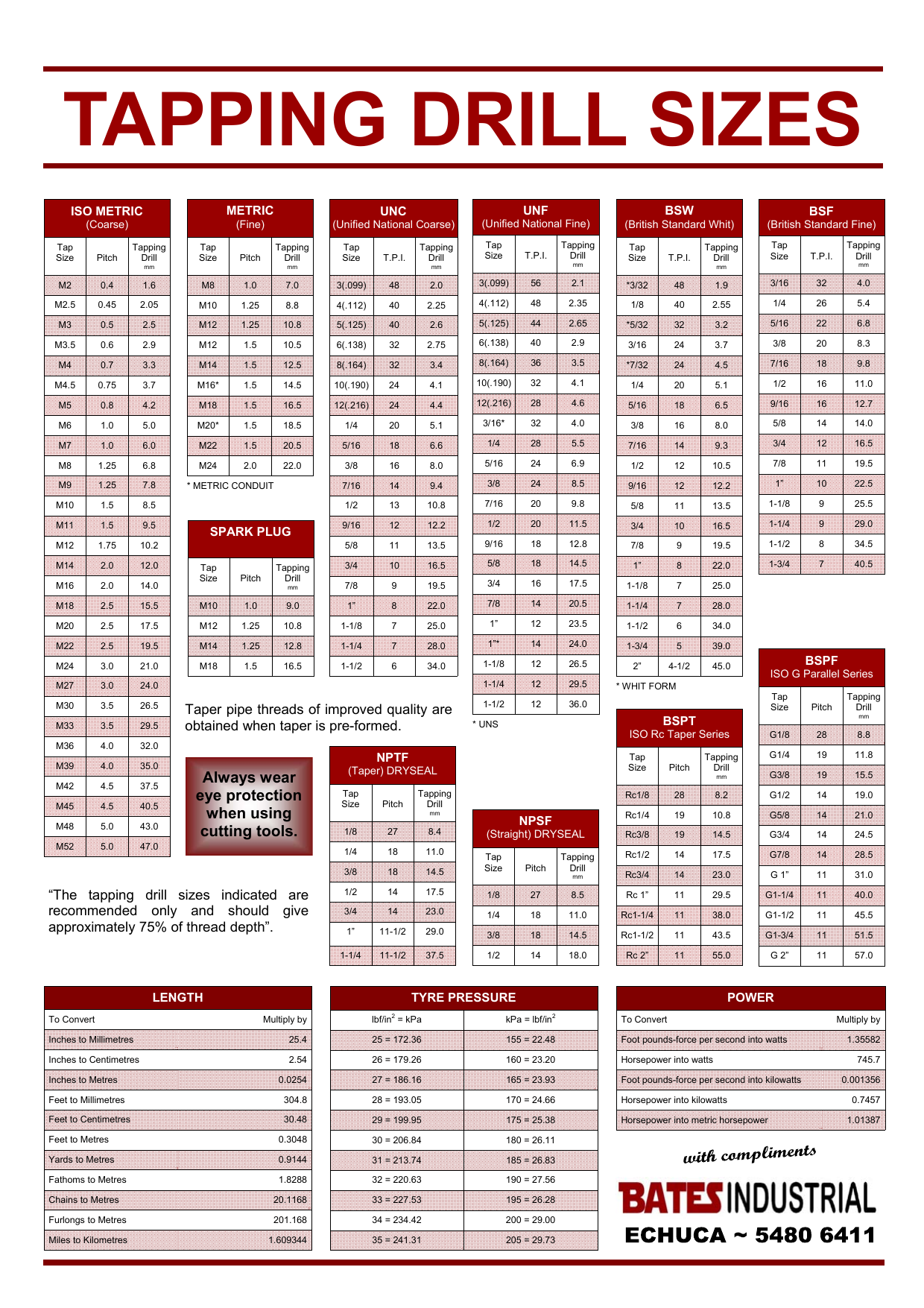

Engineering Supplies Tapping Drill Chart 3

Web first, roll taps are chipless. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Web jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Hardened steel and chilled cast iron. Web roll form tap drill chart calculator for calculation of recommended roll form.

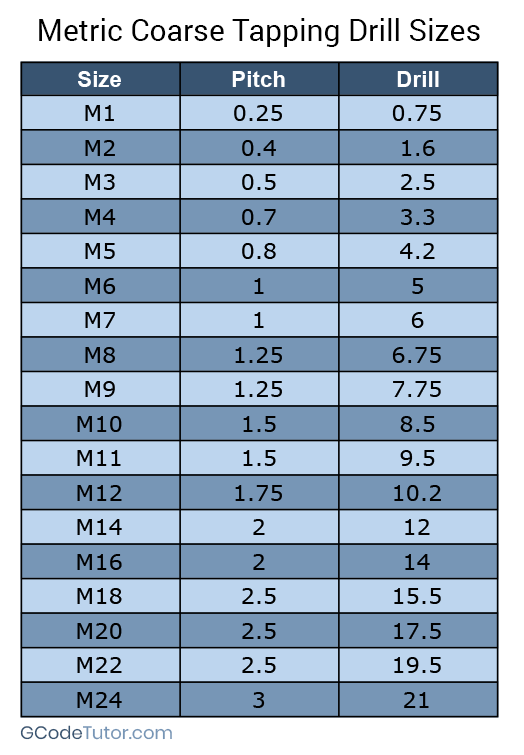

Tap Drill Charts

Hole size for inch forming taps major diameter tpi (threads/inch) % of thread hole size 4. Because they do not remove material from the hole, form taps generate no chips that must be removed. But choose out of some of these chocolate may affect your browsing experience. Calculations are done according to roll form tap drill charts which are given.

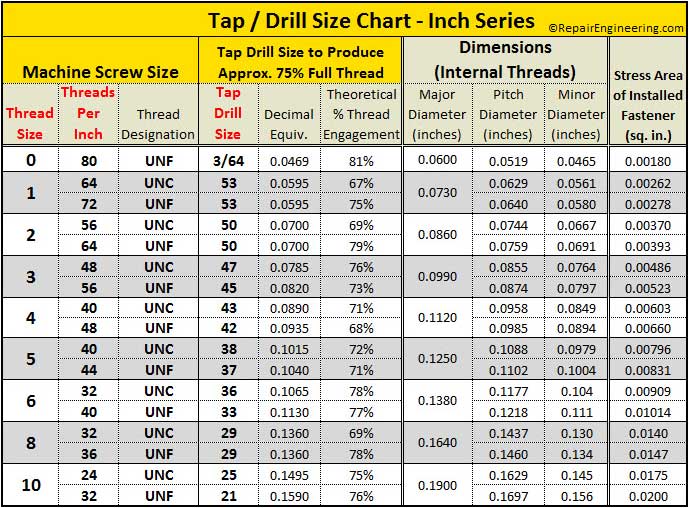

Tap Drill Chart 14+ Download Free Documents in PDF, Excel

These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Roll tapping is a process which forms a. (mm) — (% of thread desired x mm pitch) 147.06 (example m8 x 1.25 tap with 65% thread) = 8 — (65 x 1.25) = 7.45 mm. Such cookies will be stored are own browser.

Tap Drill Chart

Such cookies will be stored are own browser only with your consent. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Roll tapping is a process which forms a. Hole size for inch forming taps major diameter tpi (threads/inch) % of thread hole size 4. Web jarflo roll form pipe taps (npt.

Emuge Sti Form Tap Drill Chart Best Picture Of Chart

Web roll form tap drill chart calculator for calculation of recommended roll form tap drill sizes for unified threads. Desired thread size and % of full thread are input parameters for the calculator. Hole size for inch cutting taps major diameter tpi (threads/inch) % of thread hole size 2. Special, super and titanium alloys. Roll tapping is a process which.

Emuge Sti Form Tap Drill Chart Best Picture Of Chart

Grey cast iron, malleable and spheroidal iron. Such cookies will be stored are own browser only with your consent. Calculations are done according to roll form tap drill charts which are given in the machinery's handbook. Hole size for metric forming taps major diameter pitch % of thread hole size Hole size for inch forming taps major diameter tpi (threads/inch).

Form Tap Drill Chart Drill, Chart, Reference chart

Hole size for inch cutting taps major diameter tpi (threads/inch) % of thread hole size 2. Hole size for metric cutting taps major diameter pitch % of thread hole size 3. Roll tapping is a process which forms a. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Such cookies will be.

FREE 8+ Sample Tap Drill Chart Templates in PDF

Grey cast iron, malleable and spheroidal iron. Roll tapping is a process which forms a. Calculations are done according to roll form tap drill charts which are given in the machinery's handbook. Such cookies will be stored are own browser only with your consent. Hole size for inch forming taps major diameter tpi (threads/inch) % of thread hole size 4.

printable drill and tap chart That are Selective Derrick Website

Hole size for metric cutting taps major diameter pitch % of thread hole size 3. Grey cast iron, malleable and spheroidal iron. Calculations are done according to roll form tap drill charts which are given in the machinery's handbook. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Web first, roll taps.

Hole Size For Metric Forming Taps Major Diameter Pitch % Of Thread Hole Size

Web roll form tap drill chart calculator for calculation of recommended roll form tap drill sizes for unified threads. Grey cast iron, malleable and spheroidal iron. (mm) — (% of thread desired x mm pitch) 147.06 (example m8 x 1.25 tap with 65% thread) = 8 — (65 x 1.25) = 7.45 mm. Roll tapping is a process which forms a.

Because They Do Not Remove Material From The Hole, Form Taps Generate No Chips That Must Be Removed.

Desired thread size and % of full thread are input parameters for the calculator. Calculations are done according to roll form tap drill charts which are given in the machinery's handbook. Special, super and titanium alloys. But choose out of some of these chocolate may affect your browsing experience.

Hardened Steel And Chilled Cast Iron.

Web first, roll taps are chipless. Hole size for inch cutting taps major diameter tpi (threads/inch) % of thread hole size 2. Web jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Hole size for metric cutting taps major diameter pitch % of thread hole size 3.

— (.0068 X % Of Thread Desired) Threads Per Inch 068 X 250 — =.228 Dia.

Such cookies will be stored are own browser only with your consent. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Tapping drill size since thread forming. Hole size for inch forming taps major diameter tpi (threads/inch) % of thread hole size 4.

![23 Printable Tap Drill Charts [PDF] Template Lab](http://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-19.jpg)