Shop Drawings

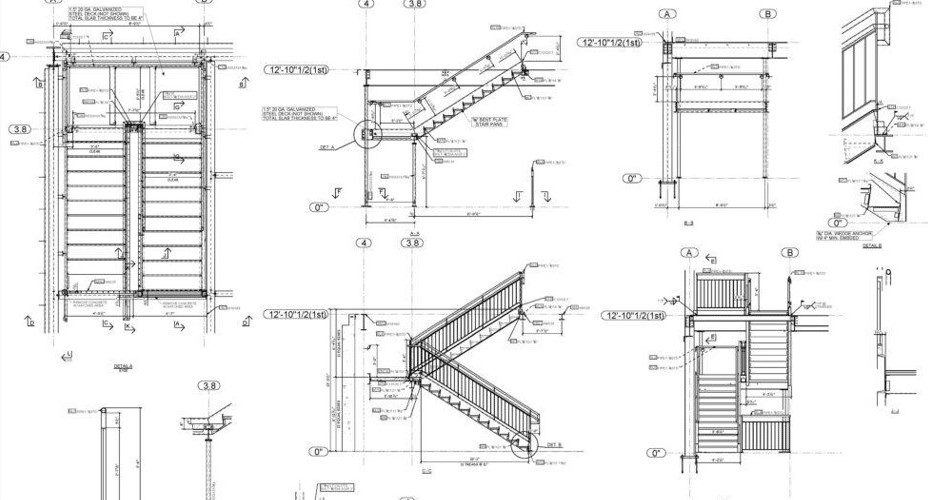

Shop Drawings - They act as an informational guide. Web shop drawings generally consist of weld maps, steel detailing drawings, pipe spool drawings, layout drawings, and welding logs. Shop drawings are a critical component in the planning, creating, and design process for structural engineers. Without them, contractors would be left to interpret design drawings on their own, leading to. Web shop drawings, a term quite familiar to those in the construction industry, but perhaps a bit nebulous to outsiders. Contractors must deal with extended lead times and strict timelines while defining final design elements. By providing a level of detail that goes beyond general plans, shop drawings help ensure that everyone involved in the. They provide a visual representation of how each component will be installed and ensure that each component is installed correctly and in the right location. Shop drawings are used as a blueprint for construction. They play a vital role in communication, quality control, compliance, project coordination, and conflict resolution.

Web what are shop drawings? [1] shop drawings are typically required for prefabricated components. The technique of numbering or marking each weld’s placement is what transforms the standard drawing into a map. Web a shop drawing is a drawing or set of drawings produced by the contractor, supplier, manufacturer, subcontractor, consultants, or fabricator. They act as an informational guide. Created by contractors, subcontractors, suppliers, manufacturers, and fabricators, shop drawings can almost be viewed as a common. Shop drawings are used as a blueprint for construction. A weld map is a drawing design used to number each of the welds within it. Web shop drawings play a pivotal role in ensuring the success and quality of construction projects. This will avoid numerous submittals that burden the project schedule or the consultant team.

Web shop drawings serve as a bridge between the design phase and the execution phase of a project. Created by contractors, subcontractors, suppliers, manufacturers, and fabricators, shop drawings can almost be viewed as a common. What is the difference between shop drawings and construction drawings? They play a vital role in communication, quality control, compliance, project coordination, and conflict resolution. While bim 3d modeling improves the quality of architectural work. The technique of numbering or marking each weld’s placement is what transforms the standard drawing into a map. These critical blueprints are an integral cog in the vast machine of a construction project. Web a shop drawing is a drawing or set of drawings produced by the contractor, supplier, manufacturer, subcontractor, consultants, or fabricator. [1] shop drawings are typically required for prefabricated components. This will avoid numerous submittals that burden the project schedule or the consultant team.

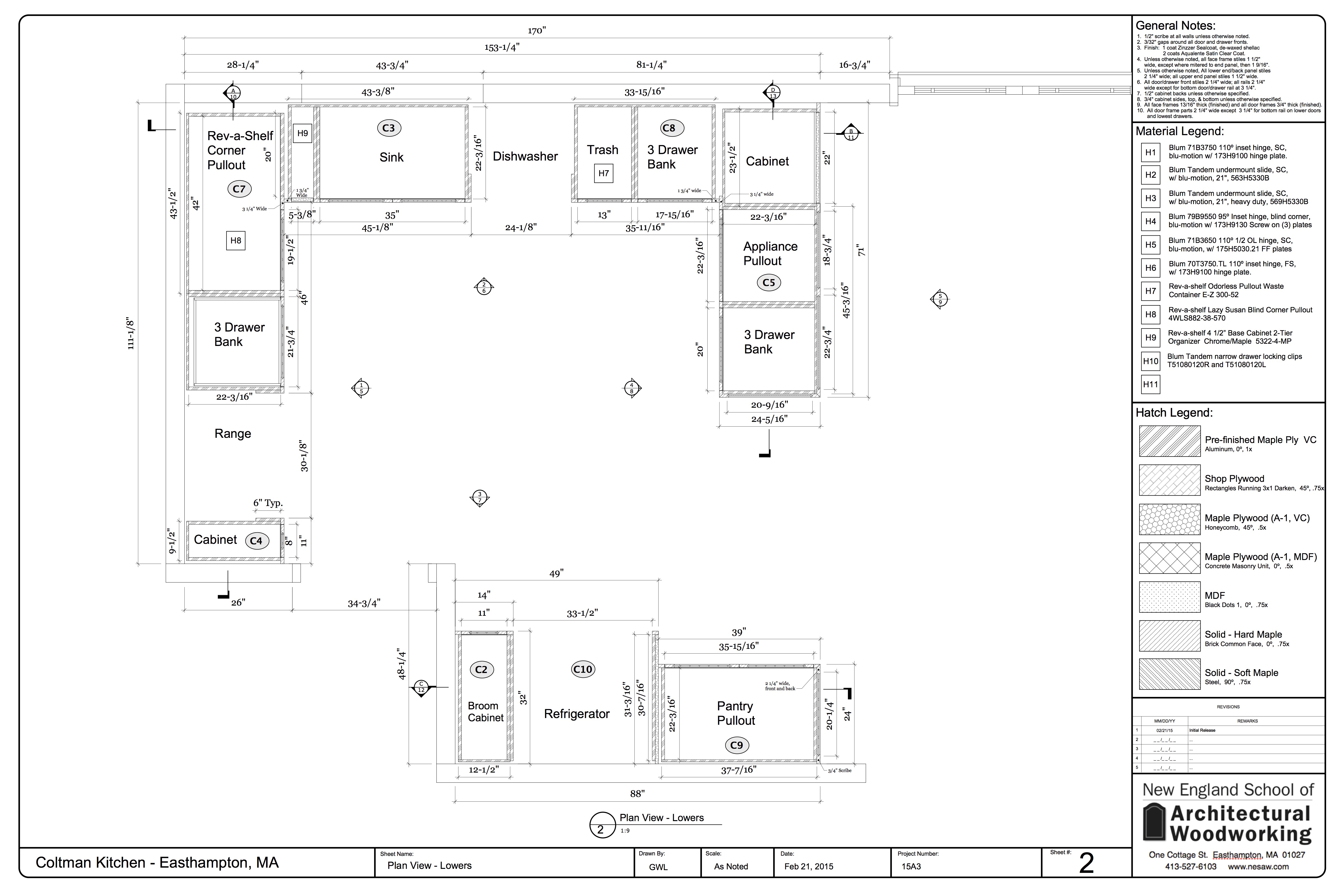

Creating Professional Shop Drawings Using SketchUp LayOut CabWriter

These critical blueprints are an integral cog in the vast machine of a construction project. Contractors must deal with extended lead times and strict timelines while defining final design elements. They provide a visual representation of how each component will be installed and ensure that each component is installed correctly and in the right location. Without them, contractors would be.

How to Draw a Shop Really Easy Drawing Tutorial

They provide a visual representation of how each component will be installed and ensure that each component is installed correctly and in the right location. This will avoid numerous submittals that burden the project schedule or the consultant team. Web shop drawings, a term quite familiar to those in the construction industry, but perhaps a bit nebulous to outsiders. These.

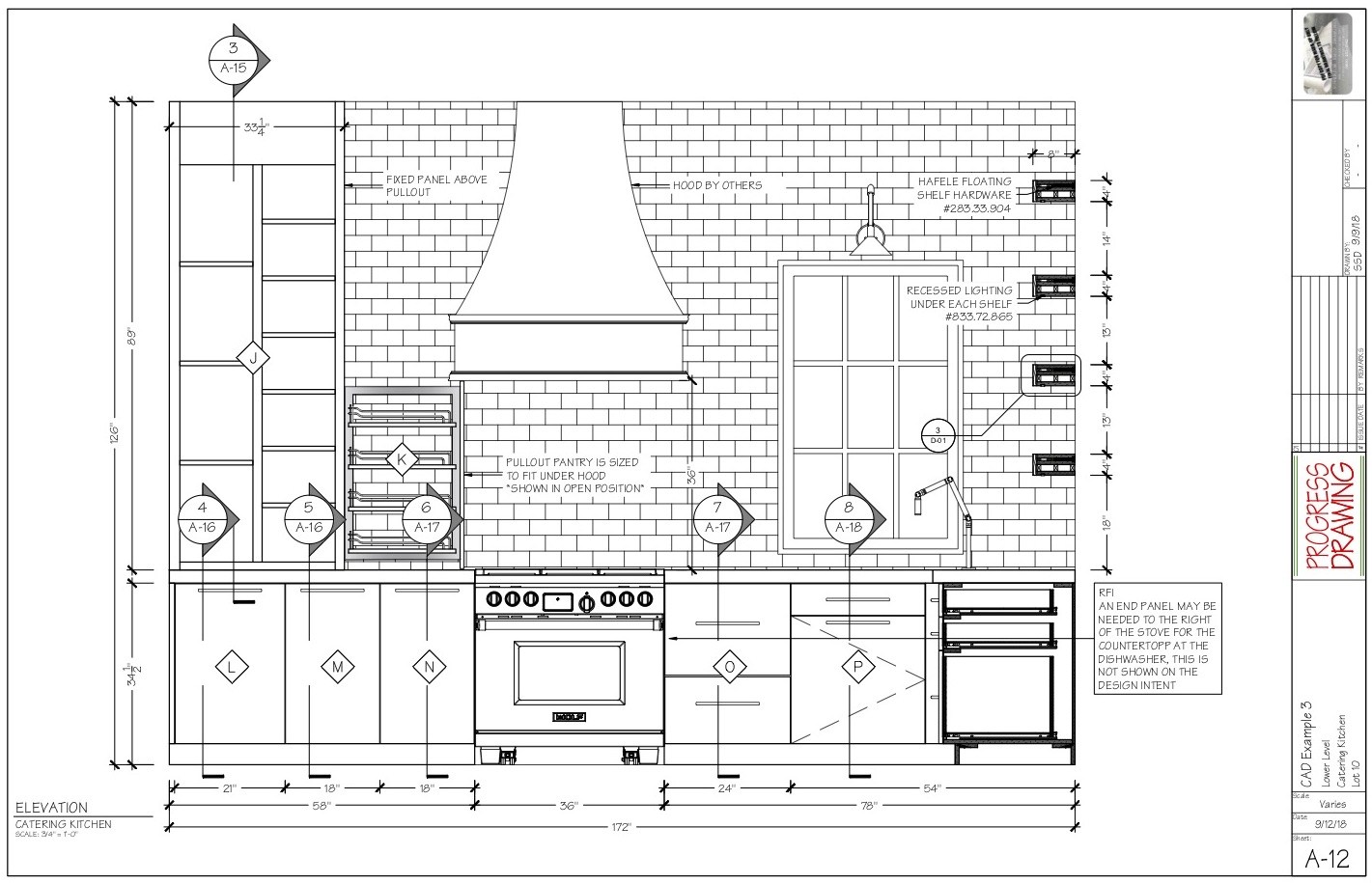

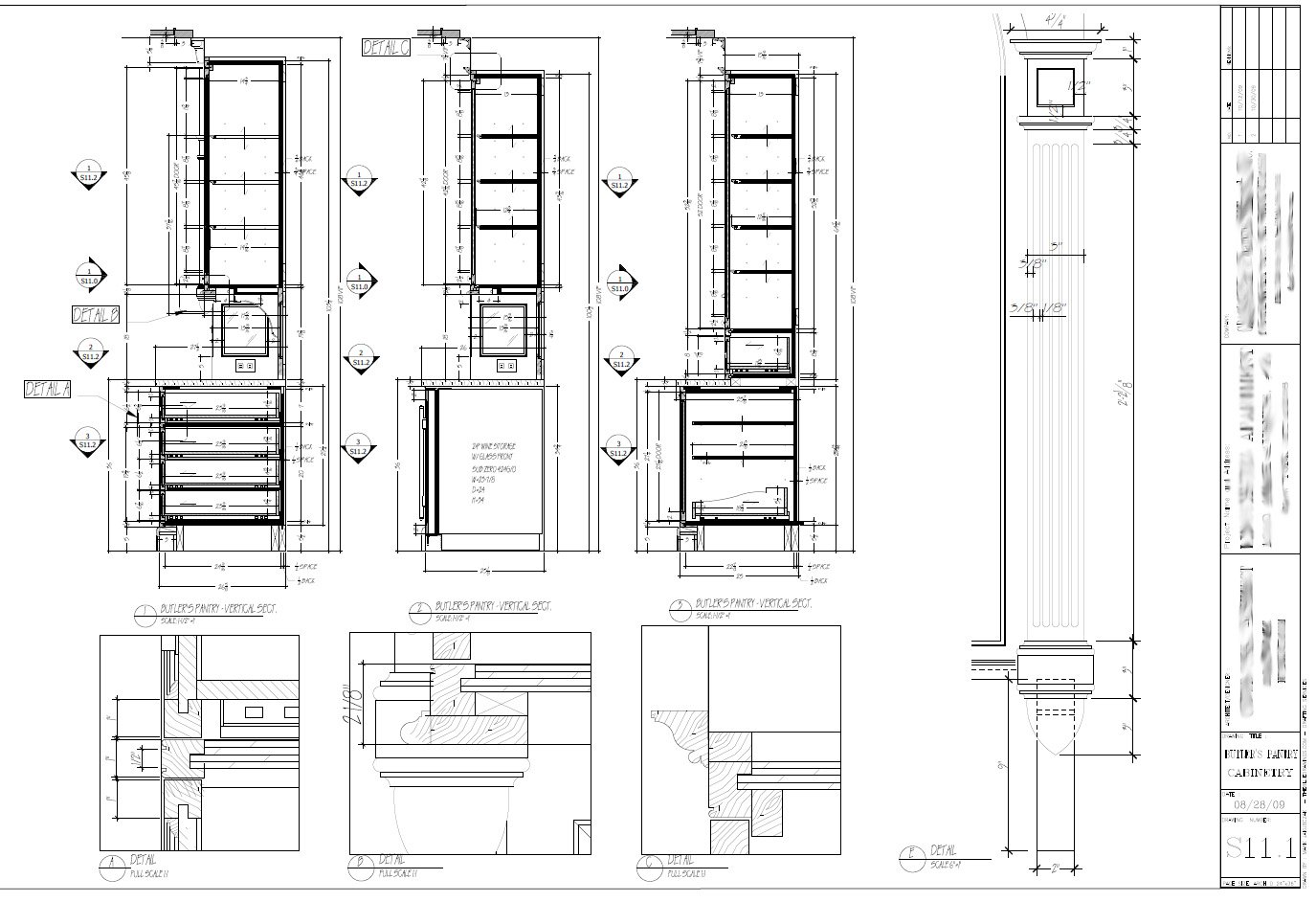

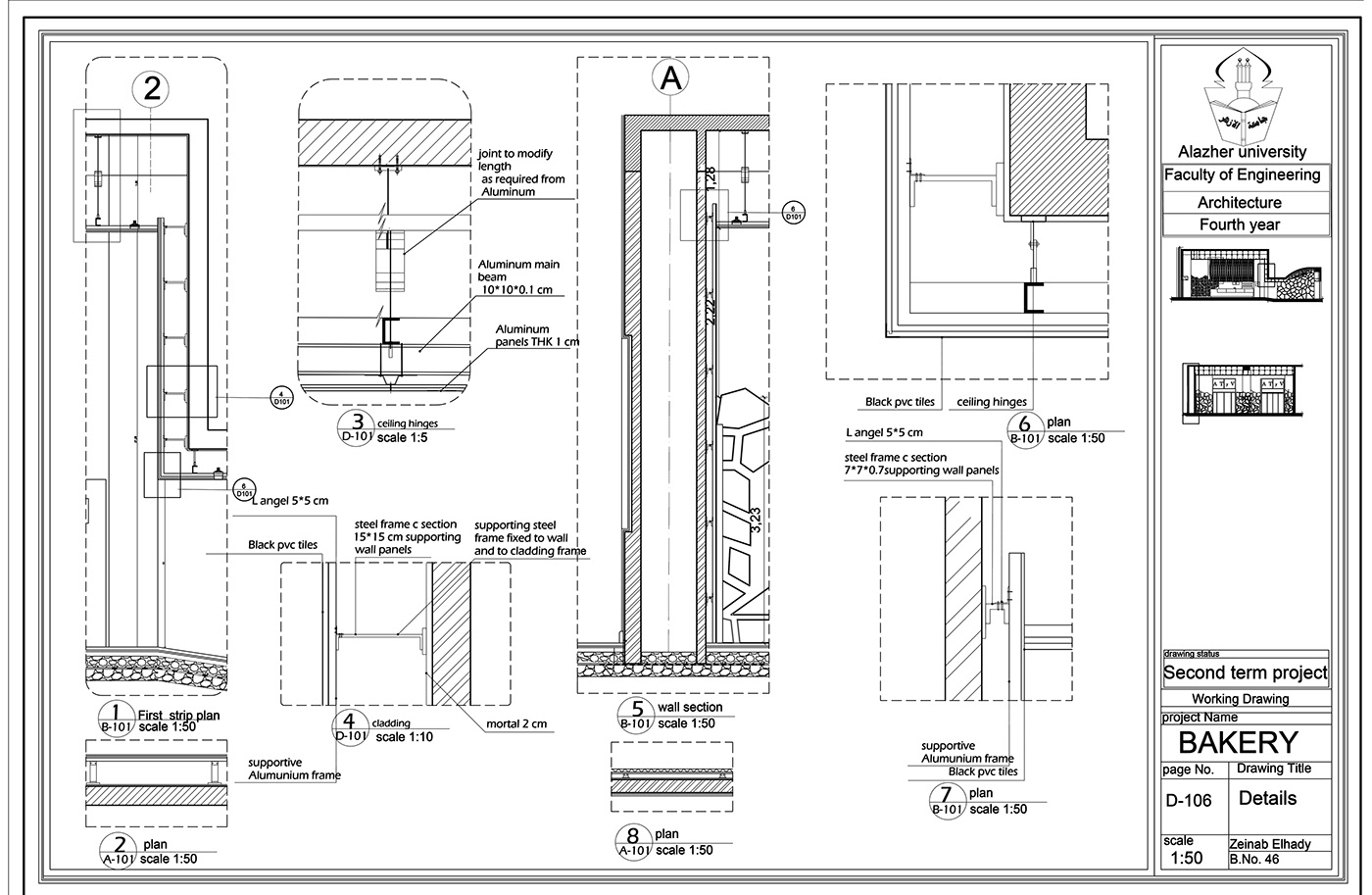

working, interior design, shop drawing, Details Behance

They play a vital role in communication, quality control, compliance, project coordination, and conflict resolution. These are created and generally prepared by engineers, suppliers, subcontractors, and contractors.shop drawings are also known as “fabrication drawings“. They act as an informational guide. Web shop drawings, a term quite familiar to those in the construction industry, but perhaps a bit nebulous to outsiders..

working, interior design, shop drawing, Details Behance

[1] shop drawings are typically required for prefabricated components. Web shop drawings generally consist of weld maps, steel detailing drawings, pipe spool drawings, layout drawings, and welding logs. They provide a visual representation of how each component will be installed and ensure that each component is installed correctly and in the right location. By providing a level of detail that.

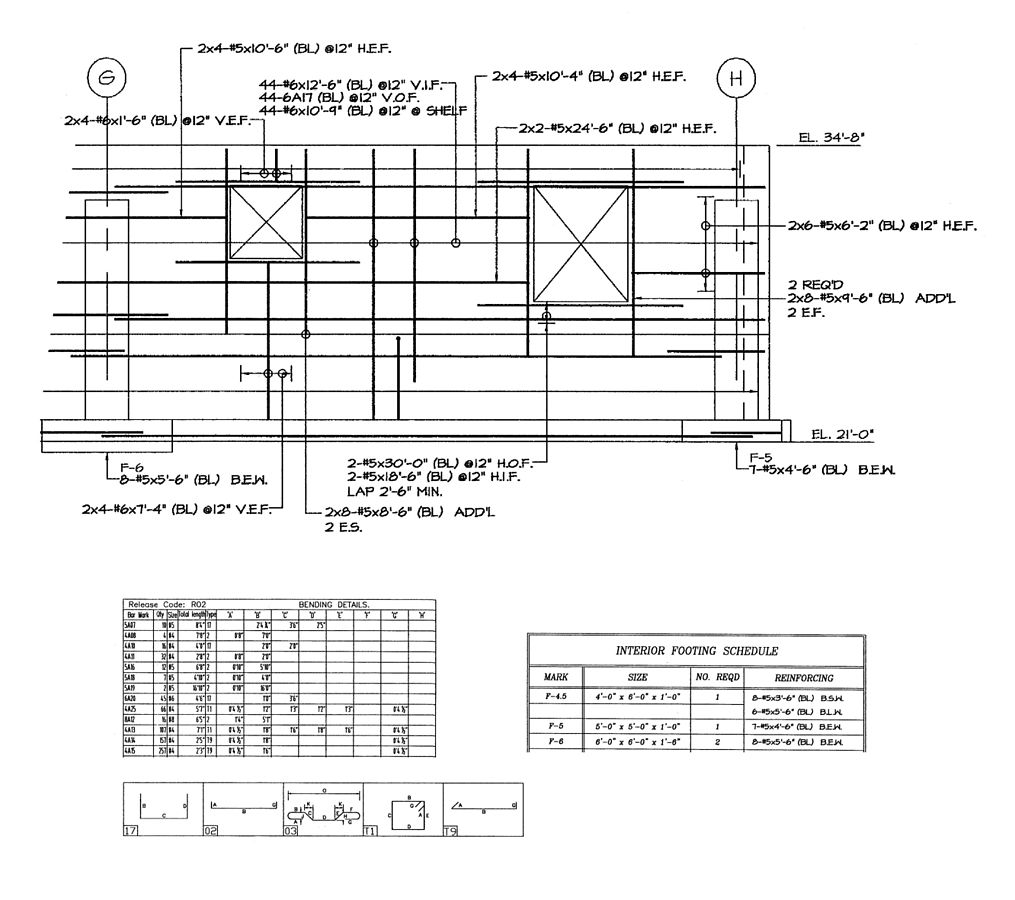

Shop Drawing at Explore collection of Shop Drawing

Contractors must deal with extended lead times and strict timelines while defining final design elements. Web shop drawings generally consist of weld maps, steel detailing drawings, pipe spool drawings, layout drawings, and welding logs. Web shop drawings, a term quite familiar to those in the construction industry, but perhaps a bit nebulous to outsiders. This will avoid numerous submittals that.

Shop Drawings

These are created and generally prepared by engineers, suppliers, subcontractors, and contractors.shop drawings are also known as “fabrication drawings“. They play a vital role in communication, quality control, compliance, project coordination, and conflict resolution. A weld map is a drawing design used to number each of the welds within it. This will avoid numerous submittals that burden the project schedule.

Creating Quality Shop Drawings Superior Shop Drawings

Web a shop drawing is a drawing or set of drawings produced by the contractor, supplier, manufacturer, subcontractor, consultants, or fabricator. This will avoid numerous submittals that burden the project schedule or the consultant team. While bim 3d modeling improves the quality of architectural work. They provide a visual representation of how each component will be installed and ensure that.

Shop Drawings Asbuilt Drawings UnitedBIM

They act as an informational guide. Web shop drawings are essential for effective communication between owners, designers, contractors, subcontractors, and suppliers, as may be inferred from the study above. Shop drawings are a critical component in the planning, creating, and design process for structural engineers. [1] shop drawings are typically required for prefabricated components. Web shop drawings, a term quite.

working, interior design, shop drawing, Details Behance

Shop drawings are used as a blueprint for construction. They provide a visual representation of how each component will be installed and ensure that each component is installed correctly and in the right location. This will avoid numerous submittals that burden the project schedule or the consultant team. [1] shop drawings are typically required for prefabricated components. While bim 3d.

5 tips for creating accurate shop drawings ShapeCUT

Web shop drawings play a pivotal role in ensuring the success and quality of construction projects. Web shop drawings are essential for effective communication between owners, designers, contractors, subcontractors, and suppliers, as may be inferred from the study above. The technique of numbering or marking each weld’s placement is what transforms the standard drawing into a map. Shop drawings are.

Without Them, Contractors Would Be Left To Interpret Design Drawings On Their Own, Leading To.

Contractors must deal with extended lead times and strict timelines while defining final design elements. Web shop drawings, a term quite familiar to those in the construction industry, but perhaps a bit nebulous to outsiders. These critical blueprints are an integral cog in the vast machine of a construction project. Web shop drawings are essential for effective communication between owners, designers, contractors, subcontractors, and suppliers, as may be inferred from the study above.

The Technique Of Numbering Or Marking Each Weld’s Placement Is What Transforms The Standard Drawing Into A Map.

Web shop drawings serve as a bridge between the design phase and the execution phase of a project. Shop drawings are a critical component in the planning, creating, and design process for structural engineers. What is the difference between shop drawings and construction drawings? Web a shop drawing is a drawing or set of drawings produced by the contractor, supplier, manufacturer, subcontractor, consultants, or fabricator.

Web Shop Drawings Generally Consist Of Weld Maps, Steel Detailing Drawings, Pipe Spool Drawings, Layout Drawings, And Welding Logs.

A weld map is a drawing design used to number each of the welds within it. This will avoid numerous submittals that burden the project schedule or the consultant team. These are created and generally prepared by engineers, suppliers, subcontractors, and contractors.shop drawings are also known as “fabrication drawings“. [1] shop drawings are typically required for prefabricated components.

Web What Are Shop Drawings?

Created by contractors, subcontractors, suppliers, manufacturers, and fabricators, shop drawings can almost be viewed as a common. They play a vital role in communication, quality control, compliance, project coordination, and conflict resolution. Web shop drawings play a pivotal role in ensuring the success and quality of construction projects. While bim 3d modeling improves the quality of architectural work.